As a professional...

Factors affecting the price of tinplate boxes

Abstract: There are many factors that affect the price of tinplate boxes, mainly including the supply and demand of raw materials, the structure of tinplate boxes, the order volume of tinplate boxes, the complexity of tinplate box printing and engraving processes, and transportation distance.

The impact of supply and demand prices

The price of raw materials for tinplate boxes is almost always changing and is the result of many factors. The relationship between supply and demand and general utilization are often the most important aspects that affect the price of tinplate boxes, and involve the ease and availability of them. The supply and demand relationship is the dominant force that affects the market price of tinplate box raw materials, and the demand status is mainly affected by the production status of machinery manufacturing enterprises. When the demand is strong, the market is in a seller's market and the market price is bullish; when the market needs to shrink, the market is in a buyer's market and the market price is bearish. For example, the market price of tinplate every year has a price cycle. Before the Mid-Autumn Festival, the tinplate is bullish. Because there are many tinplate mooncake boxes during the Mid-Autumn Festival, gift tinplate box production companies must prepare some production materials for production and use during the Mid-Autumn Festival. Reduce the risk of Mid-Autumn Festival procurement; after the beginning of the new year, most companies will have a big chance to produce tinplate gift boxes for the New Year, and there will also be a big purchase action. At the same time, during the New Year period, the factory has holidays, the production capacity will be reduced, and the resources supplied to the market will be reduced. Therefore, the year before and after the bullish year is generally bearish. The market price from June to August of each year is generally at the high price of the market. This period is when the market needs to be strong.

Overview of the tinplate raw material market

Tinplate raw materials refer to materials obtained from iron ore. In most cases, the tinplate raw material market is controlled by major producers or refiners who have the ability to convert into products. For example, crude oil and gems can be processed into various useful commodities. In most cases, unprocessed tinplate raw materials will not be sold directly on the market. The tinplates available on the market are usually tinned or galvanized sheets.

Influence of bank credit interest rate: Many tinplate raw material manufacturing companies rely on bank credit for their capital operations. If the loan interest rate increases, it will affect the company's expected loan cost. Tinplate sales companies may speed up the shipment process, causing market prices to fall; at the same time; The metal packaging manufacturing industry will also be affected, because most of the large-volume orders require loans. If the loan interest rate increases, the number of people buying transactions will be reduced, and the enthusiasm of manufacturers will also be reduced. The metal packaging market will be affected, which will affect the price of the tinplate market. .

The impact of international exchange rates: the exchange rate refers to the ratio of RMB to US dollars. The appreciation of the renminbi refers to a reduction in the ratio, which is not conducive to tinplate exports. When the exchange rate is 8, the export of one ton of tinplate is 600*8=4800 (assuming the international market price is 600 USD/ton). When the RMB appreciates, that is, when the exchange rate decreases, suppose it is 7.5, and the export of one ton of tinplate is 600* 7.5=4500 RMB, exports will decrease and China's tinplate raw material resources will increase, which will affect tinplate prices.

Difficulty of refining tinplate raw materials

The difficulty of obtaining will also affect the price of tinplate raw materials, because simpler extraction methods usually require less equipment and fewer people, thus reducing indirect costs. Labor costs may be the most controversial factor in the international raw material market. Many of the world’s minerals and processing and refining companies are located in developing countries. Manufacturers and refineries like to get together here because of lower labor costs.

Critics often worry that people working in these mines or refineries will not get fair remuneration, and the working environment and safety are below the standard. However, if they follow the standards of Western countries such as Europe or the United States, the prices of products faced by consumers may rise significantly.

Tinplate raw material purity factors

Most tinplate raw materials are graded based on purity. This is usually determined by how much other materials are mixed. For example, carbon, magnesium and sulfur are naturally present in iron. The purity standards for crops, logs, food and textile raw materials are usually called quality, which is often determined by the quality of the material, and factors such as material softness, color or taste are also considered. The fewer impurities, the higher the value and quality. Manufacturers sometimes remove impurities from materials or improve quality before putting them on the market, but this generally increases the overall price.

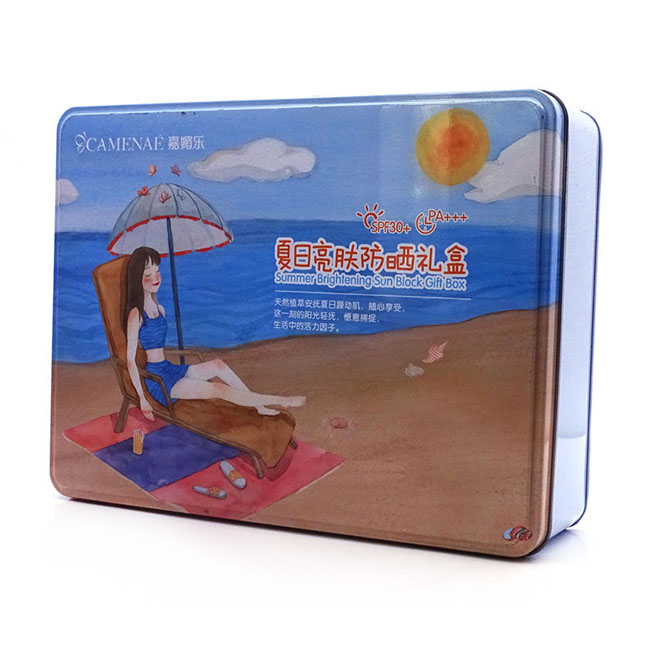

The complexity of tinplate box printing process

Because the surface of tinplate is very smooth, does not absorb ink, and has a certain hardness and thickness, printing is difficult if the printing plate is not flexible. Therefore, tinplate printing generally uses offset printing. Offset printing is an indirect transfer printing method that uses rubber The elasticity of the cloth transfers the graphics and text on the printing plate to the surface of the tinplate. After printing, the tinplate can be welded, rolled, sealed or stamped, and can be made into various specifications of barrels, cans and other containers for food, chemicals, medicine, and building materials. , Home appliances and other commodities and toy manufacturing. Generally, four-color printing is cheaper than spot-color printing for tinplate boxes.

Structural factors of tinplate box

A tinplate box, no matter how big or small, is made by multiple stamping processes, at least eight or nine processes are required, and as many as twenty or thirty processes. The number of procedures has nothing to do with the size of the tin box, mainly depends on the structure and complexity of the tin box. The more complex the structure of the tinplate, the higher the cost. The can-making is: according to the structure of the iron box, the mold master makes the corresponding mold, and the worker presses the printed iron through the mold. Some tinplate boxes seem to be similar, but due to the differences in individual structures, the order of the stamping process and the number of processes in the production process will be different. However, the basic processes of tinplate box stamping are: can lid (bottom): cutting-flashing-winding; can body: cutting corners-bending-bones-connecting bones-buckle bottom (gong bottom)-curling. Below we introduce the production process of the two tin boxes, so that everyone can roughly understand the stamping process of can making, and it is better to have a field understanding of the can making workshop.

Tinplate transportation factors

The loading address, unloading address, and route of the goods to be shipped have a direct impact on the transportation price. Under normal conditions: poor traffic conditions in remote places, complicated routes, and difficulty for large vehicles to travel, and loading and unloading places in the city's restricted traffic areas are the places most carriers are unwilling to go. In this case, the carrier vehicle requires a relatively high freight rate (because it has to bear more driving risks, the arrival of the goods does not return the goods, the return to the place where there are many sources of goods requires more fuel, and the forbidden area must be caught Risk) These factors directly affect the price of tinplate boxes.

.png)

.jpg)

.jpg)

.jpg)

Latest comments