Как поставщик...

Comment: The safety of the printing inside the tin can of dream cake

The packaging industry of dream cake tin can is an important part of the food industry. With more attention and higher requirements for food safety, people's attention to the safety of tin can packaging is also increasing, and besides paying attention to the tin can packaging material itself, the safety of printing ink on tin can packaging cannot be ignored. .

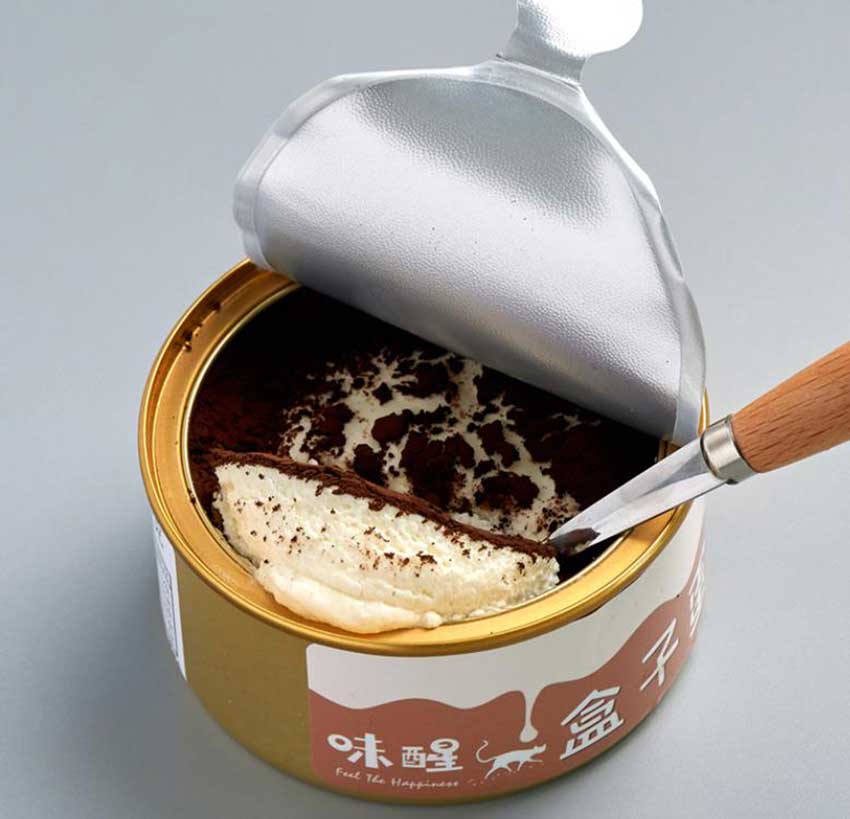

Recently, hot-selling dream cake tins, biscuit tins, tin cans will have a layer of gold or other color coating on the inner wall. If you are more concerned about food health, you may ask such questions. This coating is in the end What substance is it? Is it harmful to the human body? Why do you want to print inside the tin can of the dream cake? This article answers this question to everyone.

Printing principle of dream cake tin can

Dream cake tin can printing uses the physical properties of water and ink to repel each other, and with the help of printing pressure, the printing plate graphics and text are transferred to the iron box through the blanket, which belongs to the principle of offset printing. Due to the special physical and chemical properties of dream cake tin can and the reprocessing performance of printed matter, its printing process is quite different from ordinary offset printing. After finishing all the color registrations, a layer of bright oil should be applied to the surface of the printed tin can to increase the gloss of the printed product surface, and at the same time, it can also increase the surface hardness of the product, so that the printed ink layer has a certain degree of flexibility and corrosion resistance , All can produce beautiful and eye-catching dream cake tin can.

In addition to a certain degree of water resistance, the color inks printed by dream cake tin can also need special requirements. Because the surface of dream cake tin can is impermeable to moisture and solvents, it needs to be baked and dried, so its ink should be heat curing type. High requirements for pigments' tinting strength and durability. In addition to the basic properties of general offset printing inks, iron printing inks should also have heat resistance, strong ink film adhesion, impact resistance, good rigidity, cooking resistance and light resistance according to the characteristics of iron printing.

This special substance smeared on the inside of dream cake tin can is used to prevent the contents of the package from corroding the tin can, prevent the cake from being contaminated on the wall, and can better extend the storage time of the cake. On the curling edge of the dream cake tin can, we can clearly see that the application of this layer is not only to prevent corrosion, but also to protect the tin can packaging from being scratched and rusted by external forces. And this layer of paint can also add a bit of beauty to the dream cake tin can.

The internal coating of dream cake tin can is phenolic resin coating, epoxy-phenolic resin coating, acrylic resin coating and aluminum powder coating. It is a kind of non-toxic, harmless, odorless, good adhesion, good adsorption and flexibility. It has good corrosion resistance, and has excellent high temperature resistance. It will not produce harmful substances under high temperature heating, and will not lose the original luster and other functions.

I have heated the dream cake tin can in the microwave. After heating, the inner coating of the tin tin box has not changed at all! So it’s not like some people say that the inner coating in the dream cake tin can is not resistant to high temperature. Of course, it is not recommended to do this. You still need to use special utensils to heat things.

In the final analysis, the coating on the outside of the dream cake tin can package may be used as a barrier to prevent oxidation and protect the tin can from rust, so consumers can rest assured to buy!

Latest comments