A embalagem em caixa...

Tobacco Packaging Box

1. What is tobacco packaging

Tobacco packaging boxes are generally divided into two types, one is long strips and the other is bulk. To facilitate portability, bulk cigarette boxes are generally 5 cigarette boxes, 7 cigarette boxes, 10 cigarette boxes, 14 cigarette boxes, and 20 cigarette boxes. The materials are paper cigarette case, aluminum cigarette case, and tinplate cigarette case.

In order to achieve the purpose of smoking control and promote "smoking is harmful to health" worldwide, many countries have begun to stipulate that tobacco companies must print scary pictures of some diseases caused by smoking on cigarette boxes. At the same time, many countries have begun to restrict the sale of cigarettes with less than 20 packs, the main purpose is to reduce the smoking of minors, which has caused a certain impact on the tobacco industry. Therefore, looking for more novel packaging boxes to minimize the impact has become an urgent problem for tobacco companies in various countries.

Beginning in 2005, various tobacco companies have turned their attention to tinplate cigarette cases, because tinplate cigarette cases are novel in style, beautifully printed, not easy to break, and easy to transport, and they are deeply loved by the public.

2. The development of tobacco packaging boxes

Since the industrial revolution, tobacco packaging has made rapid development, especially in the past ten years, the packaging update is even more dizzying. Tobacco packaging materials, from soft paper packaging to white card hard packaging, to glass card packaging, to the popular tinplate packaging boxes in recent years, the introduction of high-end frosting technology, tobacco packaging boxes have been walking in the forefront of the packaging industry.

After entering the 20th century, tobacco packaging materials have become more extensive, including metal materials, plastic materials, paper materials, wood, and glass materials; and it has led to the development of packaging in other industries. At present, there are two main materials for tobacco packaging boxes used internationally: BOPP cardboard and tinplate. The packaging box structure is mainly based on hinged lid packaging boxes.

(1) BOPP cardboard tobacco packaging box (laser rainbow cardboard)

①Laser image of BOPP cardboard tobacco packaging box.

a. Under dark conditions, the paper is similar to ordinary aluminized paper without any obvious pattern, but under the condition of light reflection, the paper will have an image like a rainbow after rain, so it is called rainbow film, rainbow card paper. Good laser rainbow paper images are clear, bright and colorful. Even if a large area is printed with deep black, deep red and other background colors, the rainbow effect cannot be covered, so it is very popular in the packaging industry.

b. The laser plates used to make the laser rainbow cardboard are all wide and large, and there are no plate seams in the range of 787mm×546mm or even larger. At present, only a few companies in Europe and the United States can produce them in the world.

②The product itself has the same structure and appearance. Generally, the non-aluminized surface of the laser rainbow film is composited with paper. The aluminized surface is treated as a printing surface after printing compatibility. However, due to the difference in the characteristics of BOPP and PET films, the composite The rainbow card paper has the following differences.

a. The temperature resistance, tensile strength and paper stiffness of BOPP laser rainbow paperboard are not as good as PET laser rainbow paperboard. Especially the printing of cigarette packages generally requires glazing. If heating is required and the heating distance is longer, BOPP laser rainbow Jammed paper is easy to shrink into an arc, but PET laser rainbow jammed paper generally does not appear this phenomenon.

b. Since printing factories generally choose to print on the aluminum-plated surface, the adhesion between the aluminum-plated layer and the film directly affects the printing quality. In comparison, due to the poor polarity of BOPP film, even after corona treatment, its surface tension is lower than that of PET film subjected to the same corona treatment. Therefore, the adhesion between the aluminum layer and the film of BOPP laser aluminized film is lower than The adhesion of the aluminum layer of PET aluminized film to the film, therefore, the printability of BOPP laser cardboard is not as good as PET laser rainbow cardboard. In other words, BOPP laser cardboard printing is more difficult and prone to poor ink adhesion, especially after die cutting.

③The thickness of the PET film is generally 0.012mm and the stiffness can be guaranteed, while the BOPP film itself is soft. Generally, a film with a thickness of about 0.023mm can barely ensure the stiffness. This directly leads to the larger thickness of the BOPP laser rainbow cardboard. Not as good as thinner PET rainbow cardboard.

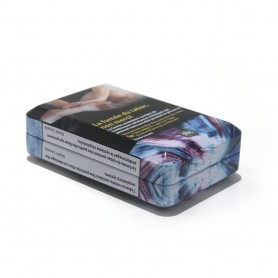

(2) Tinplate tobacco packaging box

①When printing tinplate tobacco packaging boxes, they will choose to match comfortable colors, such as bright red, light pink, orange, sky blue, rich purple and other bright colors. These colors can enhance the atmosphere and are more easily accepted by the market. They will not only attract consumers' attention. , And can evoke their desire to buy.

②The advantages of the material of the tinplate tobacco packaging box are excellent sealing, gas barrier, moisture-proof, light-shielding, taste-preserving, and the sealing is reliable, which can protect the quality of tobacco to the utmost. Different grades of tobacco have different requirements for packaging material, shape and printing. For example, low-priced tobacco is mostly made of paper packaging, while high-end cigarettes are mainly made of tinplate, which has better stretchability. Powerful, easy to print exquisite patterns and text typesetting, the custom-designed tobacco packaging tin box is exquisite and beautiful, which is easier to attract attention and has a higher grade. Whether it is ordinary iron or tinplate, the hardness and strength are very high. Tobacco boxes made of tinplate generally have a thickness of 0.2 to 0.3 mm, and various types can be customized according to customer requirements.

③ The tinplate tobacco box has strong compression resistance and drop resistance, which can better protect the tobacco from being easily deformed by bumps, squeezing and other factors during transportation. There are many advantages of tinplate tobacco packaging boxes, such as energy saving, environmental protection, recyclable use, good light-shielding and sealing performance, good moisture resistance, etc., but the disadvantage is that the cost is slightly lower than that of similar paper, plastic and other materials. Taller.

.jpg)

Latest comments