Pembungkusan kotak...

How is the 2020 Panini tin box made

What is the craftsmanship of the Panini tin box that we really like? What production process is used to make such a beautiful panini tin box? You will get a clear answer by reading this article.

The design of the Panini tin box is mainly combined with practicality and attractiveness to reflect its value. The structure of the Panini tin box looks simple and easy to understand, but it is also completed through a step by step rigorous process. These processes make the use of the Panini tin box more convenient and the appearance more attractive. Now, Szm, a professional technician from the tin box factory, will tell us about the birth process of the Panini tin box.

Friends who know a little about the production of metal containers know that the Panini tin box can be completed through six or six processes.

Panini tin box production process

The first step is to understand the customer's needs. When communicating with the customer for the first time, we will ask the customer's basic requirements such as the size, shape, product, quantity, design, etc. of the tin box. Only with this basic information can we comprehensively quote the customer and give the accurate price. Under normal circumstances, we will send the samples that meet the requirements to the customer according to the customer's requirements, and after confirming to the customer, we purchase the raw materials according to the demand.

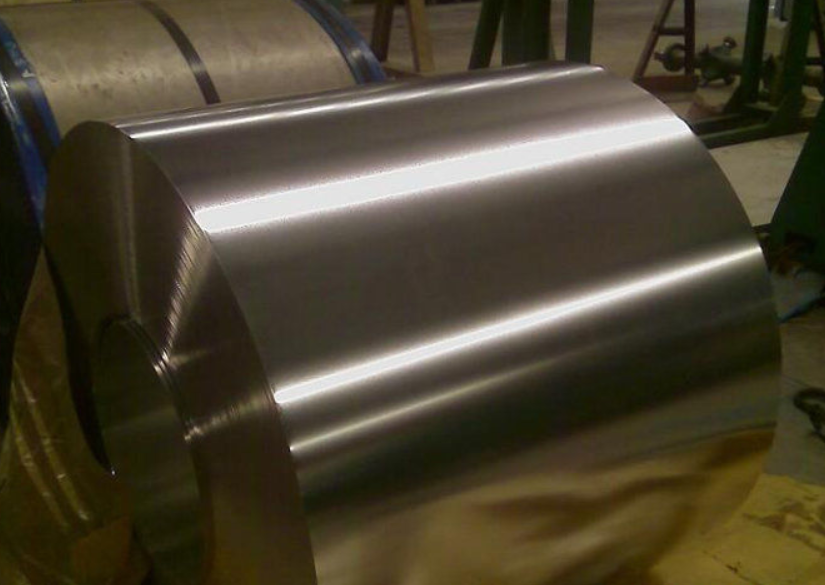

The second step is the layout and printing of the raw materials of the Panini tin box. There are two types of typesetting, one is imposition and the other is special edition. If the quantity is large, choose a special edition, and print one product on a piece of iron, so that the time will be shorter than the imposition. If the quantity is small, choose imposition and put it on a piece of iron with other products, it will take a longer time, because we have to find a suitable product and put it together. Therefore, we usually tell customers that it takes 20-30 days to customize because typesetting and printing takes a little time.

The third step is cutting, cutting the printed iron material on a cutting lathe. In the actual can-making process, cutting is a relatively simple step

The fourth step, stamping, is the most important process in the production of a panini tin box. It is necessary to know that a panini tin box must be divided into many processes to complete. The process of the two-piece can of the Tiandi Lid (separate lid) is basically the production of the lid of the opening, flashing and rolling line, the production of the bottom of the box: opening, flashing, pre-rolling, coiling, closing of the Tiandi lid, lid: opening Material, flashing, coiling, can body: opening, pre-bending, corner trimming, forming, buckle, punching, back cover. Bottom opening.

The fifth step packaging:

After the Panini tin box is stamped, it enters the finishing touch. The packaging department is responsible for cleaning and assembling, putting in plastic bags and packing. This link is a finishing work of the Panini tin box. Cleaning is very important. Therefore, the work must be cleaned before packaging, and then packaged according to the packaging method. For products with many styles, the model number and box number must be properly displayed. put. What should be paid attention to during the packaging process is the quality control of the Panini tin box to minimize the influx of defective products into the finished product, and the packing quantity must be accurate.

The above is our workflow for producing the 2020 new Panini tin box for Italian customers. If you want to know more detailed questions, please contact us.

.jpg)

Latest comments