Personalized metal...

Coffee tin can printing process

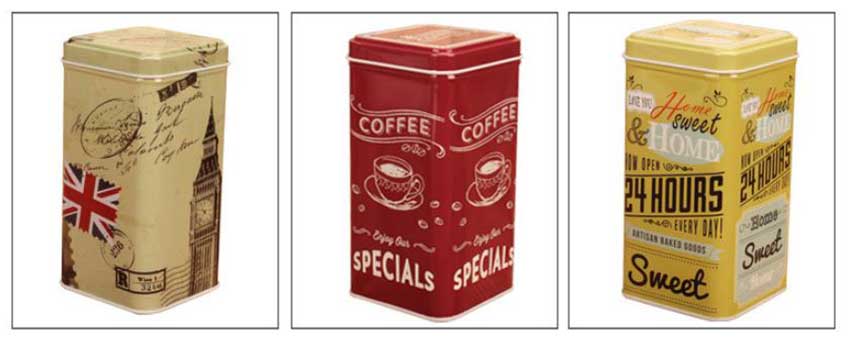

Tin cans, as a high-grade, environmentally friendly, recyclable, reusable, and highly airtight container with multiple properties, such as green and healthy, have now been used as coffee packaging by the majority of coffee merchants. The shapes of tinplate coffee cans are diversified, and the printing is becoming more and more exquisite, and they are very popular with consumers. However, many coffeemakers do not understand how the beautiful patterns on the surface of the coffee cans are printed. Cash, let me explain in detail the difference between spot color printing and four-color printing in coffee tin printing

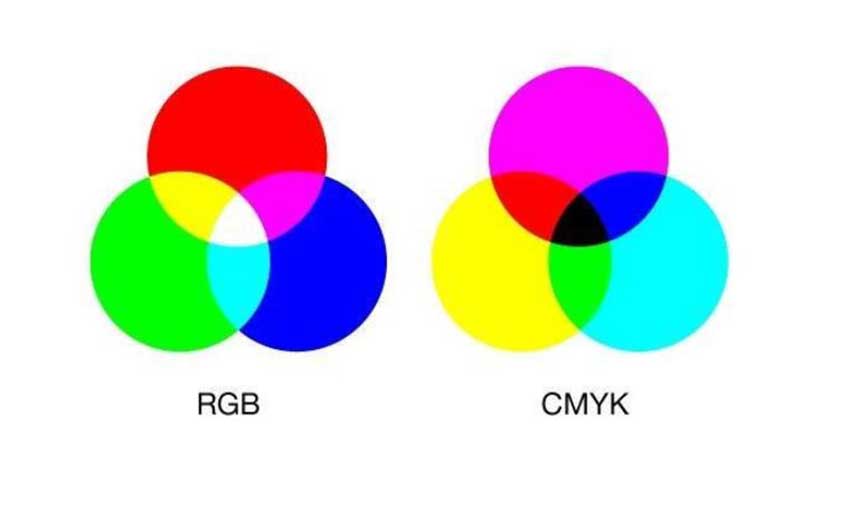

Four-color printing process for coffee tins

The four-color printing of the coffee tin box is: cyan ink, magenta ink, yellow ink, black ink (C, M, Y, K); the printing process of various colors to replicate the color manuscript. What kind of coffee tins use four-color printing? Generally, color photography is used to take photos of coffee and character expressions that reflect the colorful color changes in nature, artist's art works, or other pictures containing many different colors. Due to technical requirements or economic considerations, the picture must be scanned by an electronic color separation machine or a color desktop system, and then a four-color printing process is used to replicate the coffee tin cans.

Coffee tin can spot color printing process

Spot color refers to a printing process that uses inks other than cyan ink, magenta ink, yellow ink, and black ink, or mixes cyan ink, magenta ink, yellow ink, and black ink to replicate colors. Coffee tin printing often uses spot colors to print large areas of background colors. So what kind of product packaging is suitable for spot color printing?

The surface of the coffee packaging box is often composed of uniform color blocks of different colors or regular gradient display and text. These color blocks and text can be collided with four-color primary color ink after color separation. It is also possible to deploy spot color inks for printing, and then print only one spot color ink on the same color block. In the case of comprehensive consideration of improving printing quality and saving the number of overprints, spot color inks are sometimes selected for printing.

What is the difference in the visual effect of the color of the color block produced by the collision of the coffee tin spot color ink and the four-color ink?

The color of the ink prepared by the special color printing of coffee tin cans is obtained according to the principle of subtractive color mixing of the color material, and its color brightness is low and the saturation is high. The solid base with uniform ink color is printed in spot color. When the ink volume is appropriately increased, the change of the thickness of the ink layer will be less sensitive to color changes. Therefore, it is easier to get a uniform and thick printing effect.

The color block printed by the four-color printing process of coffee tins, because the various colors that make up the color block are mostly composed of a certain proportion of dots, when printing dots, the thickness of the ink layer must be strictly controlled, which is easy to change due to the thickness of the ink layer. And changes in printing process conditions cause changes in color intensity. Changes in the degree of expansion of outlets. This causes the color to change. And because the change of any one of the colors of the color block will cause the color of the color block to change, the chance of uneven ink color will be doubled, so the color block printed by the four-color printing process is not easy to get the ink color Uniform effect. If you can't use a multi-color machine to overprint the color of the color block at one time. It is also prone to color shift because the color of the semi-finished product is not easy to control. In addition, the four-color printing obtains the comprehensive effect of subtractive color absorption and additive color mixing of the dots, and the color block has higher brightness and lower saturation. For light-colored coffee tins, a four-color printing process is suitable.

If the color cannot be printed at one time with a multi-color machine, it is easy to have color deviation because the color of the semi-finished product is not easy to control. In general, four-color printing is not used, but spot-color printing is used. This is also a lot of printing plants monochromatic, two-color machine printing spot colors. Four-color, 8-color printing and four-color printing are more. Five-color general printing, four-color plus one spot color or over-oil etc.

Latest comments