L'emballage en boîte...

Promotional gift box production process introduction

There are all kinds of promotional gift packaging boxes on the market shelves, but what are the materials for these promotional gift packaging boxes? Ordinary promotional gift packaging is relatively simple in material and structure, and many of them are two-layer or single-layer structures, which are used for pastry packaging for bread and desserts. Our commonly used packaging materials mainly include PET, VMPET, KPET, matte PET, OPP, pearl OPP, matte OPP and other materials. These are mostly used for conventional product packaging. Tinplate and aluminum plates are generally used for high-end promotional gift packaging. , It is not used much in ordinary packaging. Paper materials generally include gray-bottomed whiteboard paper, white-bottomed whiteboard paper, and double-sided coated white cards; tinplate materials generally include frosted iron, silver polished iron, galvanized iron, etc. The strength of the promotional gift boxes made by it is higher than other papers Boxes and plastic boxes. Plastic materials have three major sections: solvent-free compounding, dry compounding, and extrusion compounding. Among them, dry compounding is the mainstream. Food packaging materials mostly use transparent boil-resistant high-barrier packaging bags, which are generally divided into two-layer structure (KPA/PE) and three-layer structure cardboard according to the size of the product. After the printing is completed, some post-printing auxiliary processes are sometimes used. Such as embossing, hot silver/gold, window opening, filming, etc. These packaging materials are common promotional gift packaging materials in our daily lives. The quality of promotional gift packaging is also related to the quality of the materials. The same promotional gift packaging made of different materials has different effects.

Promotional gift box making process

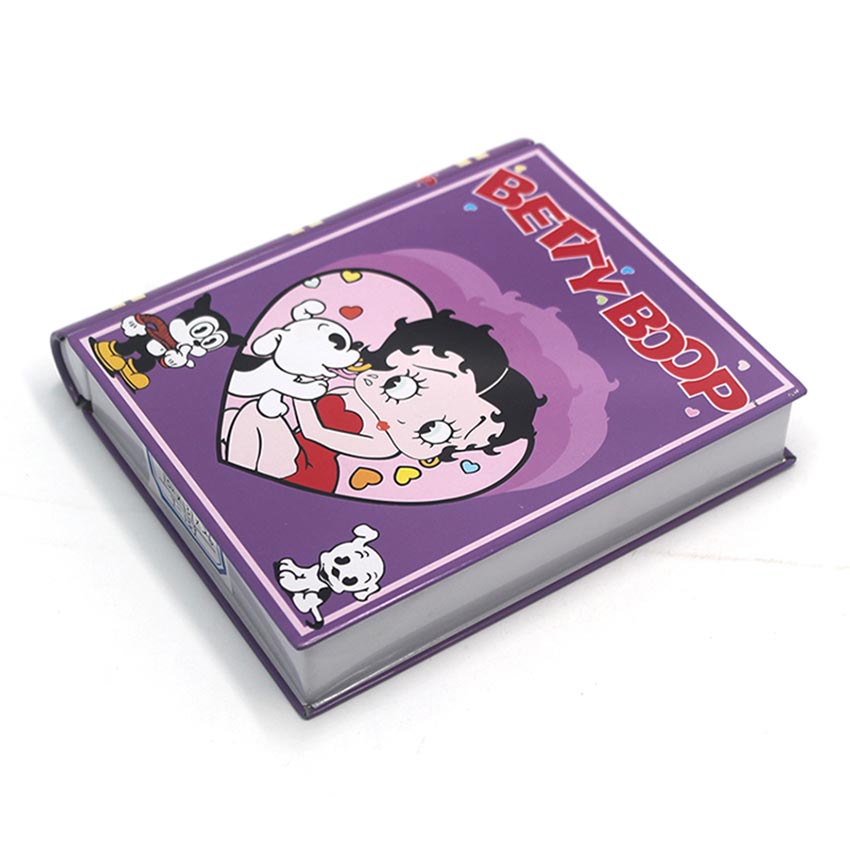

1. Production process of book-shaped promotional gift tin box (wrapped gift box):

1) Confirm the design draft

2) Confirm the sample and place an order for production

3) Scheduling production materials (purchasing tin-plated iron, purchasing inner support parts, etc.)

4) Printed packaging materials and inner stickers (printed handbags are required for matching handbags)

5) Post-process production (filming, embossing, UV, bronzing, embossing, embossing, die-cutting, etc. Some processes are selected according to needs)

6) Opening of promotional gift box

a. After printing, the panel of tin-plated iron plate material is cut, and the size is set with a cutting machine (the density board needs to be cut with a professional large saw)

b. Panel processing: V-slot machine to open V-slot, stick iron sheet

c. Enclosure processing: drilling magnet holes with a punching machine

d. Inner support processing: inner support is gray board. You need to die-cut gray board and then glue the cut silk cloth. For inner support, you need to tie the cut silk cloth on the formed foam.

7) Stamping (that is, the tin-plated iron plate is stamped into the designed shape with a mold).

8) Box assembly (You can choose the combination method according to the material needs: the lid and the box body are assembled. When assembling, keep the box clean to avoid scratches that affect the appearance.)

9.) Labeling as required. (Be careful to keep the box clean)

10) Put the inner support (asymmetrical inner support should be placed in different directions)

11) Wipe the box and pack it (the box making process takes a while, it is inevitable that there will be floating soil and stains, so we need to wipe the box to finish)

2. Production process of independent lid promotional gift tin box (upper and lower lid box)

The difference between the independent cover promotional gift box and the book-shaped promotional gift tin box is: the panel of the package box is divided into the front face, top and bottom of the box by V grooves, and the box is formed by wrapping the panel, hence the name Package box. As for the independent lid box, the upper lid and the lower bottom are separated (except the one-piece upper and lower lid), and there are some differences in the production methods:

1) Upper and lower cover boxes of MDF material The upper cover and lower bottom need to be punched and fixed with the opened plates respectively. (The upper and lower cover boxes of tin-plated iron plate materials can be opened with a "well" V groove, and the four corners are removed and then directly fixed by stamping)

2) Fasten the upper cover with the lower bottom to complete the assembly (the box with the upper and lower cover of the conjoined body needs to be connected by the connecting plate to form the upper and lower covers).

3. Put the inner support, wipe the box, and pack the box.

3. Special-shaped box production process: The special-shaped box depends on the specific box. Most of the special-shaped box is an extension of the world cover box and the package box, and the production process is similar. (There are polygonal boxes, heart-shaped boxes, round boxes, cone-shaped boxes, drawer boxes, multi-layer boxes, etc.)

4. Matters needing attention when printing promotional gift boxes

1) Pay attention to the printing effect of gift box samples

①Sampling inspection during printing. Soon after entering the formal printing, the amount of ink supply and water supply determined at the time of printing will change somewhat, so frequent sampling inspections should be carried out and readjustments should be made.

②Clamp the warning note. In the formal printing, for the place where the failure occurs, as a mark, a thin and long warning paper should be inserted to facilitate the inspection in the subsequent process.

2) Pay attention to the changes in printing water

①Pay attention to the change of water supply in the early stage of formal printing. The amount of water used during trial printing and the amount of water used after entering the formal printing will vary somewhat. Be sure to observe whether there is ghosting on the proofs.

②Pay attention to the changes in Sheung Shui during the formal printing process. Pay close attention to the influence of the heat of the main body of the machine and the ventilation conditions in the workshop on the water supply. Too much water supply will cause the ink to emulsify, which will bring a series of problems.

3) Pay attention to the change of printing ink for promotional gift boxes

①Pay attention to the ink of the ink fountain. The ink of the ink fountain is transmitted from the gap between the ink fountain roller and the ink fountain blade, and is naturally squeezed out by the weight of the ink. Therefore, the amount of ink in the ink fountain directly affects the output of ink. Therefore, pay attention to keeping a certain amount of ink in the ink fountain.

② Prevent the ink from drying on the machine. When the machine stops for a long time, such as eating or resting, the ink on the ink roller and the ink surface in the ink fountain will dry. You can use a drying inhibitor to spray on the place that needs to be prevented from drying.

③Pay attention to the uniformity of the ink. The density of the printed matter changes depending on the amount of water, room temperature, and machine speed. It should be checked frequently with standard samples to prevent uneven ink color.

④ Maintain the pH value of the wetting fluid. The addition of auxiliary agents to the ink will easily affect the pH value of the wetting fluid. If the pH value increases, it will easily cause the printing plate to get dirty, so pay special attention.

4. Pay attention to the scratches on the back of the promotional gift box

Backside smearing is the phenomenon that the ink on the surface of the printed sheet sticks to the back of the previous printed sheet due to the slow drying of the ink, the thick ink layer of the graphic and the high smoothness of the paper.

Five, pay attention to the problem of ghosting of promotional gift boxes

The so-called double image is the misalignment of the image printed with a printing plate, and double and triple images can be seen on the printed sheet. The following methods can be used:

①Print twice, observe the overprinting accuracy, check and adjust the paper pulling force of the side gauge, paper feeding, paper pressing wheel, and paper pressing mechanism.

②Check the tension of the blanket. The new blanket is easy to loosen. Pay attention to tightening in stages, but not too tight.

③Check the cylinder lining and printing pressure.

④Check the suitability of the paper. Poor paper suitability, especially paper that is wavy at the gripper, is prone to ghosting, so check it.

⑤Reduce the viscosity of the ink. The ink viscosity is high, and the paper cannot be peeled off the blanket smoothly, which makes the trailing part of the paper unstable, resulting in ghost images. The viscosity of the ink can be appropriately reduced.

Six, pay attention to check the overprinting situation

Take out 20~30 printed products in a row, twist the edges of the paper a little after they are flushed, and check whether the front and side gauges are positioned accurately.

Seven, pay attention to other work of promotional gift box printing

① Replenishment of ink, stirring and replenishment of wetting fluid.

②Dirty removal work. Dirt removal work should generally be stopped, unless there is a device that can remove dirt during operation. It is absolutely forbidden to directly remove dirt by hand during operation.

③Clean the blanket, wipe the plate and apply glue. When the ink, paper powder, or powder spraying powder is accumulated on the blanket, which affects the transfer of ink, the blanket must be shut down to clean the blanket and be safe during operation.

④ Pay attention to the abnormal phenomenon of the printing press. Pay attention to the sound, heat, vibration, smell, etc. when the machine is running, check the ammeter frequently, and pay attention to the abnormal conditions of the printing press.

8. Pay attention to confirm the number of prints

When the printing is about to end, it should be confirmed whether the number of prints is consistent with the production construction sheet. If there is a shortage that needs to be reprinted, the production management personnel shall be notified and the reprint shall be arranged in time.

.jpg)

Derniers commentaires