Comment transmettre...

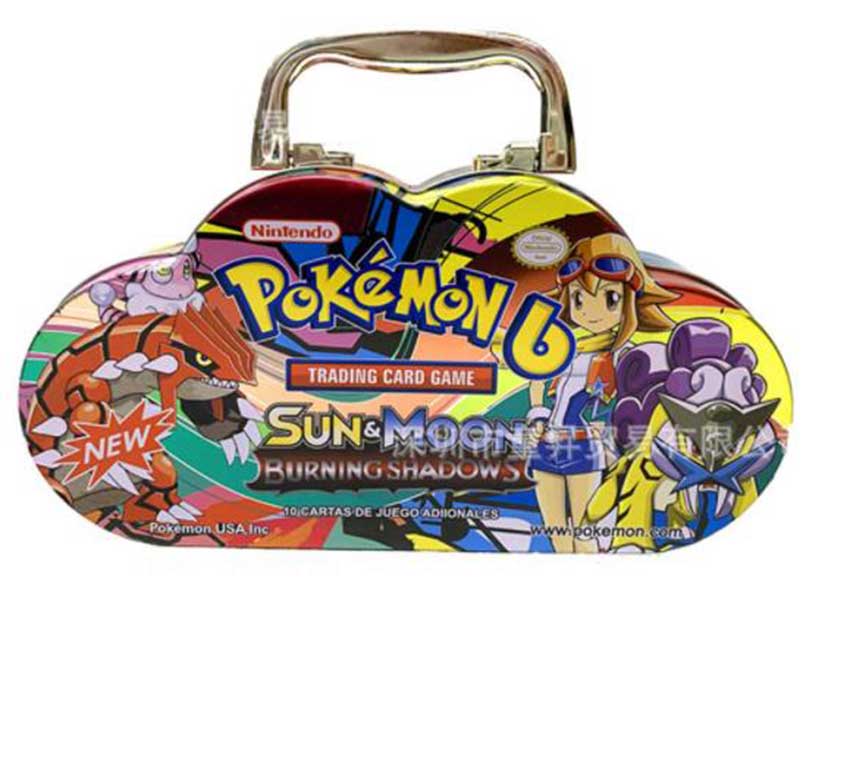

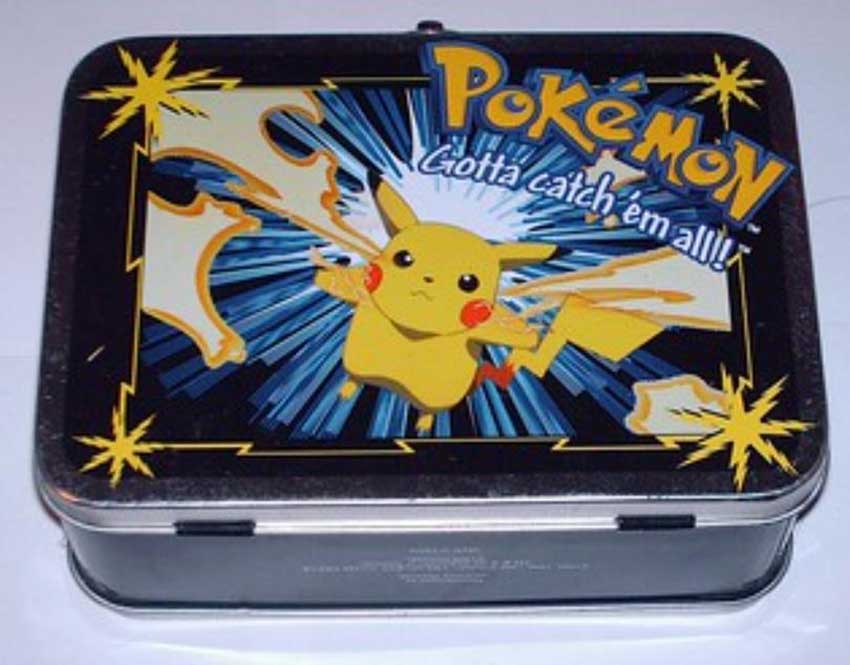

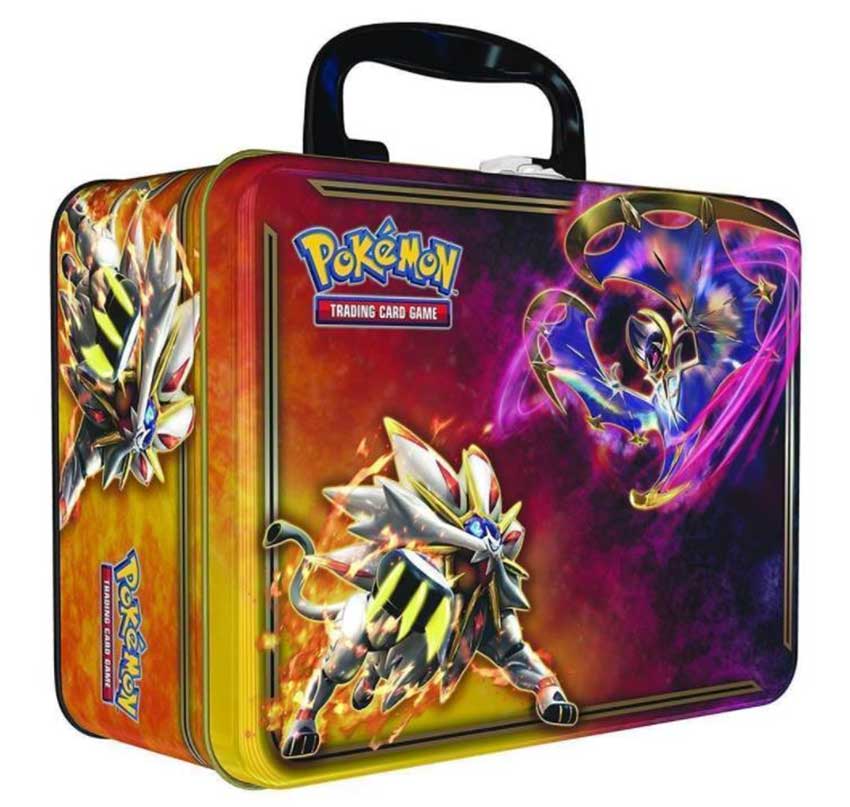

Hot selling creative pokemon lunch box tin

Reasons for the popularity of pokemon lunch box tin

Japan SKATER was established in 1938. At the beginning of its establishment, its business was mainly to produce fountain pens. With the gradual increase in the company's internal production of plastic and resin products, its business gradually shifted to mainly insulated lunch boxes and lunch boxes. In 1994, it began to expand its scale to build production bases overseas. At present, SKATER produces products all over the world. Because of its strict production requirements and strong design capabilities, it enjoys a good reputation among users.

Pokemon mobile games are super popular recently. Many people are deeply addicted to them as soon as they pick up their phones. In every corner of the city, you can find mobile game players holding their phones and looking for rare elves everywhere. Even the things around Pokemon are very popular. The most popular recently is the pokemon lunch box tin

The lunch box is shaped like Pikachu in Pokemon, made of food-grade tin-plated iron, and has a hinged lid structure with a handle. It is a popular brand. The shape of the pokemon lunch box tin is very interesting. Using the "Pokemon" manager style, the cute pattern design is super fun! The lunch tin box has a capacity of 570ml, suitable for children or adults. In addition to the main body, there is also a bento strap, which is convenient for fixing the bento box. Product specifications: 14.5*12*11cm; This Pokemon Pikachu bento tin box has a large capacity and is suitable for friends to use for dinner.

Material characteristics of Pokemon potty tin box

The pokemon lunch box tin is made of food-grade tin-plated iron. Tin-plated iron refers to cold-rolled low-carbon sheet or double-layer pure tin-plated steel strip. Tin mainly plays a role of rust prevention and rust prevention. The Pokemon lunch box combines the strength and formability of steel with the corrosion resistance, solderability and beautiful appearance of tin, and has the characteristics of corrosion resistance, high strength, and good ductility.

With the improvement and improvement of printing technology and processing technology, the application of pokemon lunch box tin has become more and more extensive. At present, the production capacity is continuously improving, and the requirements for the quantity and quality of metal packaging are getting higher and higher. The continuous and rapid development of the food industry has brought a broad market space to the pokemon lunch box tin container industry.

Due to the metal decoration charm of the pokemon lunch box tin that is airtight, preserving, light-proof, and robust, the pokemon lunch box tin has a wide coverage in the packaging lunch container industry and has become the most versatile lunch box. With the continuous enrichment of various calcium carbonate materials, DR materials, and chrome-plated iron, it has promoted the derivation and development of Pokemon bento tin boxes.

pokemon lunch box tin has strong antioxidant capacity, and its styles are diverse, and the printing is exquisite. Therefore, the pokemon lunch box tin container is very popular among consumers and is widely used in friends gatherings and class gatherings.

Printing process and requirements of pokemon lunch box tin

pokemon lunch box tin made of tin-plated iron requires ink when printing on tin box:

(1) The printing ink is required to have good adhesion and mechanical properties

Because the pokemon lunch box tin made of tin-plated iron needs to go through more than ten processes such as cutting, bending, stamping, stretching, etc., it is required that the printing ink has good adhesion to the tin-plated iron and corresponding mechanical properties . In order to improve the adhesion of the ink, it is necessary to print a white ink base on the pokemon lunch box tin before printing the pokemon lunch box tin. White ink is the basic hue of all printed patterns and has high brightness. After adding other high-energy inks, the brightness of all colors can be improved to form color gradations.

(2)pokemon lunch box tin printing requirements for printing white ink

The surface of the pokemon lunch box tin is silver-white (or yellow) with metallic luster. It needs to be painted or printed white before printing the color graphics. Due to the limited ink coating capacity, the monochrome machine often needs to be printed twice. White, its whiteness can reach 85%. White is an important standard for the printing quality of the pokemon lunch box tin. It requires white ink to have a good bond with the primer. After repeated high-temperature baking, it will not yellow, and it will not decolorize after high temperature steaming. Applying primer can improve the adhesion of tinplate cans and have good adhesion to white ink. The primer usually used is epoxy amine based, light in color, will not yellow after repeated baking, does not age, has good elasticity and impact resistance.

(3) pokemon lunch box tin printing requirements for colored inks

The colored ink used on the pokemon lunch box tin, in addition to a certain degree of water resistance, also has special requirements for it. Since the surface of the pokemon lunch box tin has no water and solvent and needs to be dried, the ink should be thermosetting. There are high requirements for the coloring ability and durability of pigments. In addition to the basic properties required by general offset printing inks, according to the characteristics of the printing iron, it should also have the characteristics of heat resistance, strong ink film adhesion, impact resistance, good hardness, cooking resistance and light resistance.

(4) Drying process of pokemon lunch box tin printing ink

In pokemon lunch box tin printing production, the drying of ink is a complicated physical and chemical reaction process. It is necessary to reasonably control the drying speed of the ink and master the physical and chemical mechanism of ink drying in order to effectively perform fast printing operations and ensure product quality. Drying the ink too fast will reduce the normal transfer performance of the ink and affect the normal production; cause the printing plate and the ink roller surface to become weaker, the color of the ink becomes lighter, the ink becomes dry, and the ink transfer is blocked; the drying layer of the printing plate is outward Expansion; Excessive desiccant will increase ink adsorption and make the blank part dirty. However, if the ink dries too slowly, it will cause difficulties in overprinting, blocking, and blocking. , The hardness is reduced; it is easy to cause scratches during the transmission process. Therefore, the drying speed of the ink should be appropriate, not too fast or too slow.

Printing process of pokemon lunch box tin

1) The lithographic printing process of the pokemon lunch box tin

The biggest feature of lithographic printing is that the printed pattern (the ink-stained part) and the non-printed pattern are on the same plane. Lithographic printing is to print ink on a rubber roller, and then use a pressure roller to print on the tinplate. Because the printing plate will not directly touch the tinplate ink and will not stain, the pokemon lunch box tin suitable for high-quality printing will be overcome even if the tinplate finish is not good.

2) The letterpress printing process of the pokemon lunch box tin

Letterpress printing means that the graphic part of the layout is higher than the non-graphic part. The ink on the ink roller can only be transferred to the graphic part of the layout, and the non-graphic part does not require ink, thus completing the printing. A traditional printing technique. After rolling ink on the engraving plate of the pokemon lunch box tin, the tinplate is stamped. The pressure printed on the pokemon lunch box tin engraving can be adjusted as needed to form a deeper Three-dimensional feeling.

3) UV printing process of pokemon lunch box tin

After irradiating ultraviolet rays with special ink, it will dry printing. It is suitable for tin-plated iron that is not easy to dry, or other flat materials, such as tin-plated products.

4) Screen printing process of pokemon lunch box tin

Screen printing is a method of hollowing out the printed part on the printing plate, allowing the ink to transfer through the mesh. When the substrate is made of tin-plated iron, aluminum plate, plastic and other materials, or curved surfaces such as boxes, cans, or special printing requirements such as floating surface effects, screen printing is mostly used.

5) The lithographic printing process of the pokemon lunch box tin

Plane printing is a relatively mature printing method at present. It is a fast and stable large-scale printing technology. It is suitable for mass printing of pokemon lunch box tin. It is a very good and economical method in the case of large printing volume. s Choice.

6) Screen printing process of pokemon lunch box tin

Screen printing is a traditional process of printing with a screen made of nylon thread. In pokemon lunch box tin printing, only a single color or several colors can be used for register printing. Because it belongs to semi-manual production, if there is color overlap, it is not suitable for products with high precision requirements.

7) The silk screen process of pokemon lunch box tin

After the surface of the pokemon lunch box tin is silk-screened, it must be pre-treated. The surface pretreatment process is also called pre-press processing. The pretreatment methods for the surface of iron cans include degreasing, polishing, wire drawing, oxidation, sand surface treatment, painting, etc. This method can be used alone or in combination according to the different requirements of the product and the condition of the underlying material to achieve the desired effect.

The pokemon lunch box tin has many advantages such as high strength, good molding performance, and product compatibility, and has established a good brand effect in the market. Therefore, consumers in various countries generally welcome this kind of lunch container, which is a metal lunch box packaging with a large amount in the world.

Manufacturing process of pokemon lunch box tin

1) Cutting process: The printed pokemon lunch box tin can be cut and cut according to the row of cutting beds. When cutting the mattress, pay attention to whether the operator is cutting according to the knife line and whether the length is consistent and uniform. Whether workers scratch each other when unloading, etc., the quality must be checked at the initial operating station.

2) Stamping process: It is to press the iron sheet into shape on the punching machine. This is the most important work of making cans. Usually, a can is divided into many processes to complete. The general process of a two-piece can with an independent lid is: lid: open material-flash-coiling. Bottom: Cutting-flashing-pre-coiling line-coiling line. If the pokemon lunch box tin is hinged, then the lid and the body will each have an additional process: hinged.

In the pokemon lunch box tin stamping process, the product is usually the most worn out. Pay attention to whether the work operation is standardized, whether the product surface is scratched, whether the coil is sewn, and whether the button is fastened. The usual practice is to arrange the production of large samples for confirmation before the production of large goods, and to produce according to the confirmed large samples, which can reduce a lot of trouble.

Summary: Each of the above processes can affect the quality of the pokemon lunch box tin, so we must pay attention to it. Only by producing samples, operating in accordance with regulations, and mutual supervision can produce good quality. If you want to know more about the making of pokemon lunch box tin, please contact us. We are a professional manufacturer of lunch tin boxes in China, with a professional production team to solve your problems.

.jpg)

.jpg)

.jpg)

Derniers commentaires