As a professional...

Catégories de blogs

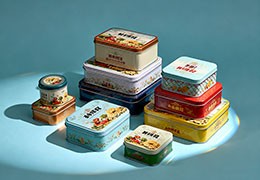

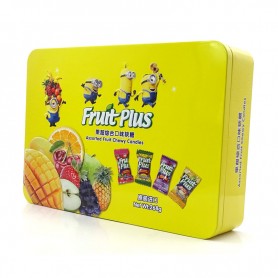

- Actualités sur les boîtes en fer blanc (371)

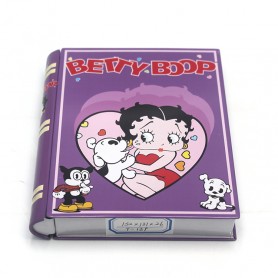

- Coffret cadeau de vacances (47) click

- 832 / 5,000 Où acheter une boîte en fer blanc personnalisée ? (217)

- Processus de fabrication de boîtes en fer blanc (252)

- Nouvelles de l'usine de boîtes en fer blanc (107)

- Nouvelles de l'industrie de l'emballage (331)

Derniers commentaires