As a Custom...

Production standard requirements for food-grade metal storage boxes!

The food-grade metal storage box is a storage box made of tin-plated thin steel plate through different processes such as welding, stamping or buckle bone, which can be used to package and protect items. When the finished production of the food-grade metal storage box is completed, the finished iron box needs to be inspected to see if its quality meets the relevant standards.

Common production standards for metal storage boxes mainly include the following four aspects:

1. The standard of the main viewing surface: place the front of the food-grade metal storage box with pictures and texts directly in front of and under the sunlight, and the outer surface that can be observed: main parts (the parts of the printed surface that reflect the theme of the pattern, text, marks and barcodes) ) There should be no scratches, and minor scratches on minor parts (not more than 0.3mm*20mm on the printing surface without iron scratch marks) are allowed to be no more than 8; the curling edge is smooth, tight and uniform; there is no obvious indentation, No cracks, ink layer does not fall off; the error of the pattern on both sides of the interface is not more than 0.5mm; the welding is firm, the solder joints are even, there is no leakage, no breakdown, no pitting, the ribs are complete, the transfer is continuous, the transition is smooth, and there is no obvious Handover traces, no cracks, parallel to the upper mouth of the tank. The contour of the concave-convex graphic is clear, full, without cracks, and registered with the printed pattern. The error of the main part is not more than 0.3mm, and the error of the minor part is not more than 0.5mm.

2. The standard of the main parts: reflect the position of the pattern, text, metal box mark and bar code of the main body of the food-grade metal storage box. It is required to be consistent with the company's sample draft. The text and pattern must be clear and correct, without missing printing, missing characters, incomplete strokes, no obvious position shift, and no defects such as blurred printing.

3. Standards for scratches: no more than 0.3mm*20mm on the printed surface of the food-grade metal storage box, and no iron scratch marks are shown.

4. Non-frontal standard: the surface of the food-grade metal storage box other than the main view, such as the back, side, bottom, inner surface, etc. Color: It must conform to the confirmed standard sample and be within the upper limit/standard/lower limit of the sealed sample. Cleanliness: There should be no dust, oil, rust and other pollution inside and outside the iron tank. Flatness of tank bottom: fall flat, allowable deviation see QB 1878-93 regulations. Leakage rate: not more than 8%. Coordination: The buckle is moderately tight and easy to buckle. Compared with the sealed sample, the gap allows a tolerance of 0.5mm.

Of course, it is far from enough to check whether the finished food-grade metal storage box is qualified. It is also necessary to check the leakage caused by the iron box trachoma, whether the printing is correct and complete, whether the welding is symmetrical, and so on.

Nowadays, food-grade metal storage boxes have been unanimously recognized by the market in terms of product appearance and material, and many consumers are also more inclined to use food-grade metal storage boxes. What is the reason for this phenomenon?

First of all, the metal storage box is a rigid packaging container, which is made of tin plate stamping or supplemented with other materials. The packaging material has a certain degree of flexibility, rigidity and higher compressive strength, and is not easy to deform compared with bag-like flexible packaging containers.

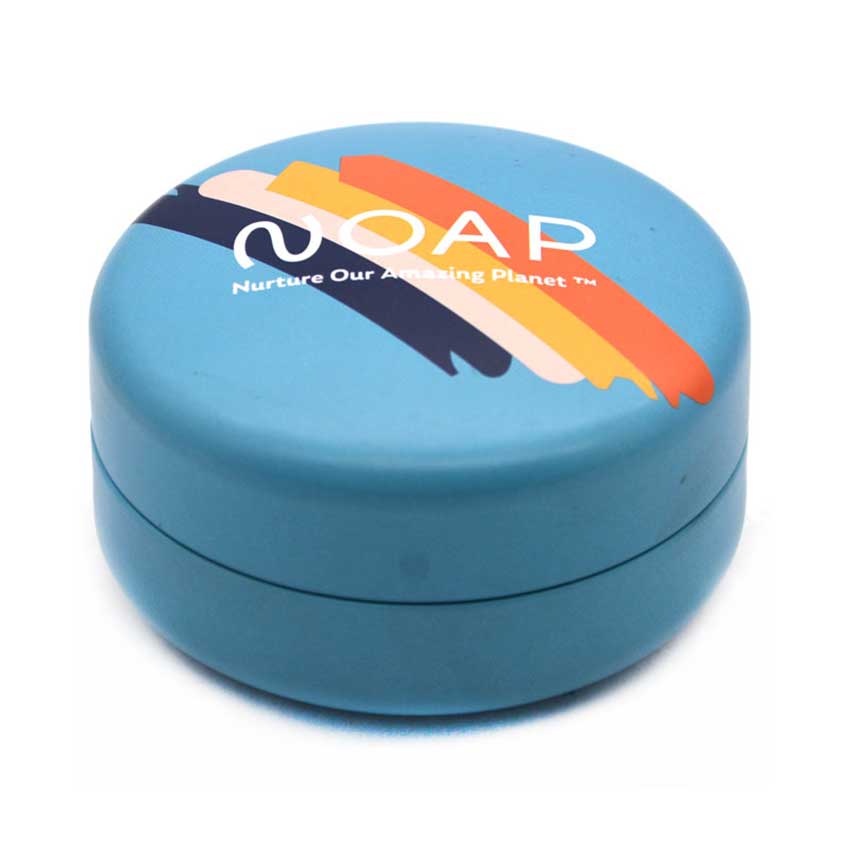

Secondly, the appearance of the metal storage box is changeable, and printing technology can be used to achieve various flat patterns and colors on the surface of the metal storage box, which is beneficial to increase the visual impact of the product and play an effective promotional role. If it is made of paper composited with metal plates or plastic materials, it can replace rigid packaging containers made of glass, ceramic, metal, and plastic in many cases.

At the same time, the metal storage box generally has a large capacity, and the packaging can be completed by manual or mechanical filling action, which is relatively simple to use.

The production process of food-grade metal storage boxes is more stringent than general packaging boxes, and involves a wider range. In the United States, the requirements for food storage boxes have risen to be the same as food inspection standards, and packaging boxes must meet food-grade standards. It can be seen that people attach great importance to food safety. As a professional tin box company, Shangzhimei explains in detail what are the basic requirements for food-grade metal storage box packaging:

The first basic requirement is safety. Because the metal storage box is to be in direct contact with the object, safety is very important, and the most basic thing is to be harmless to the human body. Ensure that the metal storage box meets the national sanitation regulations. If it is an export tin box, it must meet the relevant sanitation standards of the FDA and the importing country.

The second basic requirement is airtightness. Because food is usually spoiled and deteriorated by microorganisms, the metal storage box must have reliable airtightness, so that after the food is heated and sterilized, it can no longer be contaminated by external microorganisms.

The third basic requirement is corrosion resistance. A large part of the food contained in the metal storage box has certain nutrients, organic acids and certain compounds, which will decompose during the high temperature and high pressure sterilization process, thereby increasing the damage to the metal storage box. Therefore, in order to ensure the long-term storage of food, the selected iron can must have good corrosion resistance.

The fourth basic requirement is convenience. As a container for storing food, it must be convenient for consumers to carry and eat, and it must have the conditions for long-distance transportation.

The fifth basic requirement is to be suitable for industrial production. The metal storage box has to withstand various mechanical stamping, crimping, welding and other processes during the production process, and the demand is large and mass production is required, so it must be equipped with factory mechanization, Automated production requires high efficiency, stable quality, low cost and can meet the needs of modern production management.

.jpg)

Últimos comentarios