As a Custom...

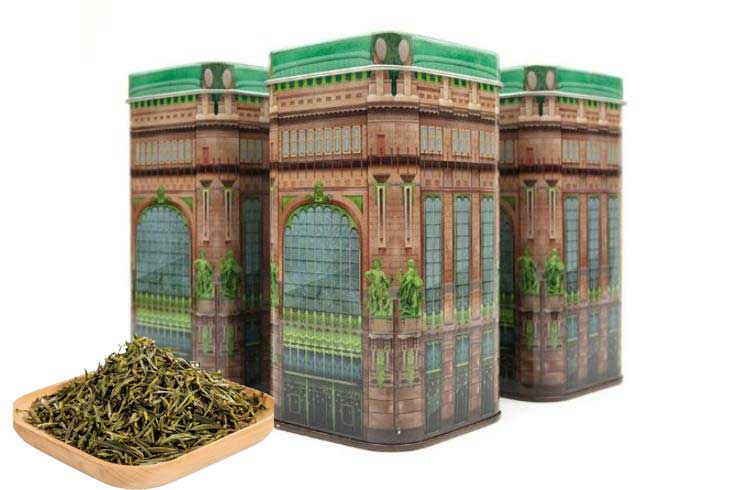

Advantages of tea tin can packaging

Good physical properties: Compared with other packaging materials, such as plastics, laminated glass, paper products and utensils, iron cans have high compressive strength, good rigidity, and are not easy to crack. Not only can it be used in small and medium-sized markets to sell packaging, but it is also a key container for large and medium-sized shipping packaging.

Excellent high barrier: Iron cans have better barriers than all other raw materials. They have good resistance to temper, water resistance, light blocking, and fragrance retention. In addition, they have reliable airtightness and can maintain products reliably.

Complete processing and high manufacturing efficiency: The production and manufacturing of iron cans has a long history, and the processing technology has a complete set of production line equipment to match it. The production and manufacturing are highly efficient and can consider the packaging needs of various commodities.

Exquisite decoration: The metal composite material has good packaging and printing characteristics; the pattern and trademark are gorgeous and beautiful, and the packaging materials produced are attracting attention. It is a high-quality market packaging.

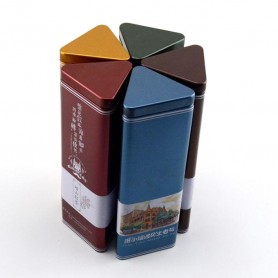

Various shapes: iron cans can be made into various shapes depending on the difference, such as square cans, oval cans, round cans, oval, ladder, etc., which not only considers the packaging requirements of different commodities, but also uses packaging materials It is even more transformative and promotes market sales.

The production of tea tin cans

1. The first process of making tea tin cans is to print the tin sheets according to the design samples. Under normal circumstances, customers will provide samples to the tin box manufacturer to follow the colors. There should be no stains during the printing process, and the printing must be very strict in accordance with the template. If you don't pay attention, there will be printing color errors.

2. In the second process, the iron material printed in the front is opened, and the size of the knife edge is cut evenly.

3. The third process is the main process of making tea tin cans, forming and stamping the cans. In general, a complete iron tea can has to make the lid and the bottom of the can separately, and it takes a dozen to twenty processes to complete.

The process of stamping can not be careless. This process is the most expensive product. Every link must be strictly implemented. Whether there is any scratch on the surface of the product, whether there is a lot of seams in the coil, and whether the button bone is fastened. After the stamping is completed, the final finishing work is to be done. The packaging department cleans and packs the products. Every corner of the tea tin cans must be wiped clean to minimize the influx of defective products into the finished product.

An exquisite tea tin can packaging does not lie in its value, but in a sincere blessing from the giver to a friend. Shangzhimei can provide the most complete canning process, just to better serve the majority of partners!

.jpg)

Últimos comentarios