Looking for high-end...

The production process and advantages of tea tin cans

1、Introduction

Tea is a dry product that is dried or air-dried. It is very easy to absorb moisture and return moisture and cause deterioration. It has a strong absorption of moisture and odor, and the fragrance of tea is very easy to volatilize. Therefore, when the tea is stored improperly, It is very easy to cause the taste of tea to change. Therefore, scientific utensils and methods should be used to preserve tea. From ancient times to the present, everyone has been continuously changing, from the original porcelain, paper, bamboo, and plastic to the current tin can packaging. It can be said that with the verification and improvement of the ancestors over thousands of years, the development of tin can packaging to today proves that tin cans are the best tea packaging containers. Advanced technology and perfect design make tea tin can packaging products continue to shine.

With the promotion and implementation of sustainable development policies in various countries, the requirements of tea packaging are economical and environmentally friendly; the requirements of pollution-free, strong sealing, and moisture-proof are advocated, and tea tin cans have also emerged. Tea tin cans are generally made of tinplate. The packaging material has no peculiar smell, has good moisture resistance, is extremely tight, and can well reduce contact with the air. Tinplate is made of tin-iron alloy, which is corrosion-resistant, non-toxic, and high-strength , Good ductility characteristics. Therefore, tinplate has become the main material for making tea tin cans.

Nowadays, there are three ways to preserve tea: iron can preservation method, ceramic jar preservation method and bag storage method. These three methods have different requirements for the temperature, humidity, and shading of the natural environment when storing tea. After long-term applications, I found that the three types of containers are suitable for storing tea in iron cans and porcelain, but the price is fully considered. Because of the exquisite printing, convenient carrying and novel styles of tin can packaging, it is more suitable as a gift to express the emotions among relatives and friends, and is deeply favored by the sales market. When people find the best tea container with tin cans as the packaging, the quality of the tin cans, color matching, cultural characteristics, safety and other content have become important conditions for everyone to evaluate the packaging.

2. The advantages of tea tin cans

1) Opacity: In addition to the deterioration of tea, light can also cause changes in the quality and grade of tea. The tea leaves are more prone to deterioration when exposed to light (especially green tea). The opacity of the tinplate makes the preservation rate of tea leaves the highest, and preserves the original tea juice, color, taste and aroma.

2) Good airtightness: The barrier properties of the packaging container to air and other volatile gases are very important for the preservation of nutrients and sensory quality. Metal cans with low oxygen permeability can better protect tea leaves, which is also the best feature of tinplate cans.

3) The reduction effect of tin: The tin on the inner wall of the tinplate will interact with the oxygen remaining in the container during filling, reducing the chance of food ingredients being oxidized. The reduction effect of tin also prolongs the shelf life of tea.

In addition, tinplate tea cans also have a heat-proof function, which completely isolates the influence of environmental factors, prevents color food from changing due to light, oxygen, and moisture, and will not weaken due to the overflow of aroma or be affected by environmental odors. Pollution and taste change, so the stability of food storage is better than other packaging materials.

4) The iron can products are recyclable, safe, environmentally friendly and harmless. The production process is relatively advanced and can be mass-produced; the tea iron can products conform to environmentally friendly packaging. After recycling, it is beneficial to environmental protection and can also create value.

3. Why should tea be stored in iron cans?

Tea is a dry product that is sun-dried or air-dried. It is very easy to absorb moisture and cause qualitative changes. It has strong absorption of moisture and peculiar smell. The main reason why tea is prone to spoilage is that it is not tightly sealed, which makes tea The moisture and peculiar smell in the air are absorbed, and the original flavor is lost. And the more expensive the tea, the easier it will change its flavor. Storage in iron cans can solve this problem well. The tinplate tea cans are tightly packed, which can effectively block the contact between the tea and the air, and have a good effect on preventing moisture, oxidation, light and peculiar smell. At the same time, the tin box itself has no peculiar smell and will not affect the original fragrance of the tea.

Put the tea leaves into the tin can, close the lid, and place the tin can in a cool place. This will not only prevent the tin can from rusting, but also slow down the aging and deterioration of the tea. The tea stored in this way, no matter how long it is left, when it is taken out and re-infused, it will still be fragrant and refreshing.

4. Components of tea tin cans

According to the structure of tea tin cans, they are generally divided into two categories: two-piece tin cans and three-piece tin cans; two-piece tin cans and three-piece tin cans can be stamped into any shape, such as round tea tin cans, square tea tins Iron cans, and other special-shaped tea cans that can be formed.

The two-piece tea tin can is a metal tin made of two parts: an iron can lid and a can body with a bottom. The can body and can bottom are hollow-shaped whole processed by the stretching method. This molding method is a stamping and stretching process, so the two-piece iron can is also called a stretched can.

Three-piece tea tin cans, both the can body is one piece, and the lid and bottom are each one. Three-piece tin cans are very common in the market at present. Common in daily life, such as Wanglaoji beverage cans, mooncake tin boxes, etc., are all three-piece tin cans. .

Tea tin cans are classified according to shape: divided into round cans, rectangular cans, square cans, triangles, special-shaped cans (heart-shaped / oval / car-shaped / cartoon animal-shaped /), etc.

5. Printing process of tea tin cans

1) Printing principle

The printing of tea tin cans is based on the physical properties of water and ink repelling. With the help of printing pressure, the printing plate graphics and text are transferred to the tin box via a blanket, which belongs to the principle of offset printing. Due to the special physical and chemical properties of tinplate tea cans and the reprocessing performance of printed matter, the printing process is quite different from ordinary offset printing. After finishing all the color registration, a layer of bright oil should be applied to the surface of the printed tin can to increase the gloss of the surface of the printed product, and at the same time, it can also increase the hardness of the product surface, so that the printed ink layer has a certain degree of flexibility and corrosion resistance. , All can produce beautiful and eye-catching printing effects.

2) Printing process

① Letterpress printing

A traditional printing technique in which metal movable type or metal engraved plate is rolled with ink and then imprinted on paper. The pressure on the paper can be adjusted according to the needs to form a rather deep three-dimensional impression.

② No ink imprinting (bumping)

A processing technology that uses metal plates but does not heat, does not use tin foil, and does not stick to ink to directly press on the paper. It is suitable for presenting the original texture of the paper or expressing it in a minimalist style.

③UV printing

It is printed with the characteristic of drying when the special ink is irradiated with UV light. It is suitable for paper that is not easy to dry, or other flat materials such as acrylic and wood.

④ Brush gold on the side

Hot stamping gold foil on the sides of piles of books or business cards can echo the hot stamping on the front and back, presenting a high-level texture.

⑤Offset printing

Lithographic printing is a fast and stable mass printing technology. It is widely used in various paper materials and can use various inks. It is a very good and economical choice in the case of a large number of production requirements.

⑥Screen printing

It is a traditional process of printing using a screen made of nylon thread. Most of the paper printing can only be used for single-color or several-color registration printing. Because it is semi-manual production, it is not necessary if there is overlapped color. It is suitable for productions with high-precision requirements.

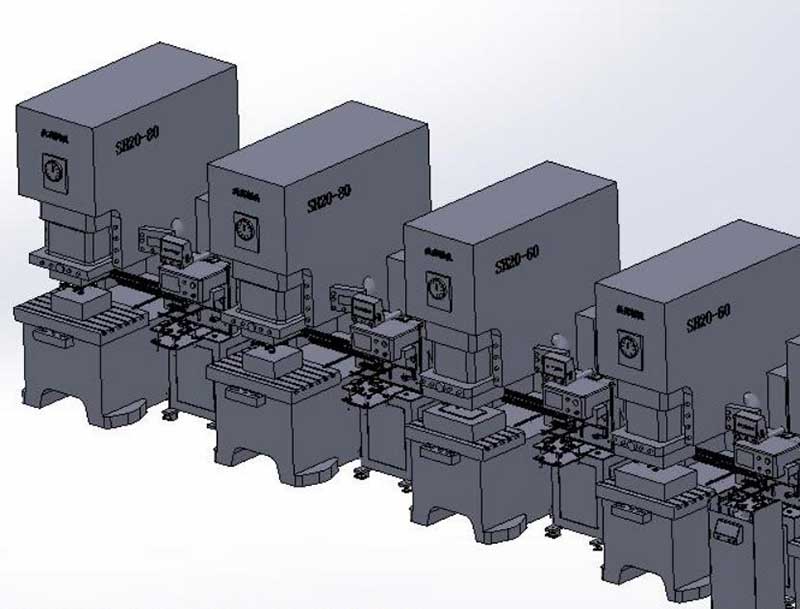

6. Stamping process in the production of tea tin cans

Stamping is a metal plastic processing technology. The blanks are mainly tinplate plates. The die is installed on a press. By applying pressure, the process is completed in an instant, and the tinplate material is processed into the required shape and size of the tin. Finished or semi-finished products. Stamping is the main process of making tea tin cans roughly divided into: Lid: opening-flashing-coiling. Bottom: cutting material-flashing-pre-coiling line-coiling line. The process of sealing the bottom (buckle bottom) tank with an independent lid, the lid: opening-flashing-winding. Can body: open material-pre-bend-cut corners-forming-buckle bone-punch body (buckle bottom)-back cover. The bottom process is: cutting.

7. Cleaning and testing requirements for tea tin cans

1) Before using the tea tin cans, food safety inspections should be carried out, and there should be no accumulated water or moist debris in the tin cans;

2) The trunnion of the tea tin can should be forged, and its safety factor should not be less than 9;

3) If the trunnion wears more than 9% of the original shaft diameter, it should be scrapped; the trunnion should be inspected by non-destructive flaws once a year, and records should be kept together.

.jpg)

Latest comments