As a Custom...

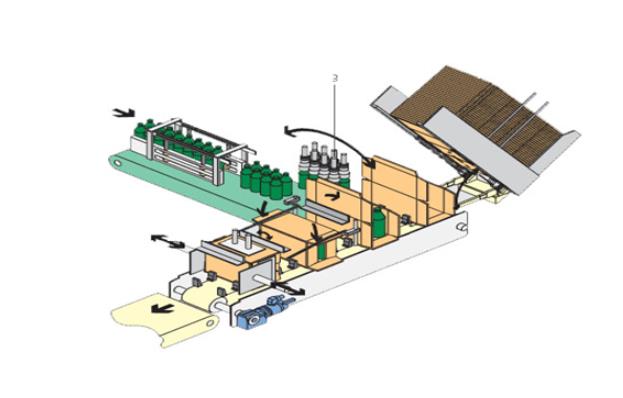

Packaging box production process

Packaging box production is a complicated process. Different professions generally think that you will be asked to make production today and you can get it right away. In fact, every industry has its own workflow. A qualified packaging box needs to go through a number of processes. Made. Today, Qiandao Packaging will give you a detailed description of the packaging box production process, roughly divided into the following steps.

1. Plate making

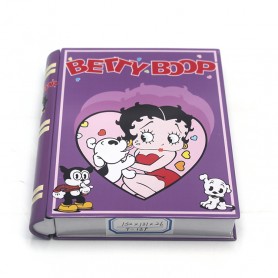

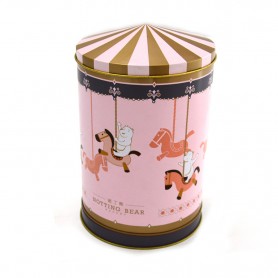

Plate making and links are extremely important, because this process directly affects the integrity of the product, and the current technology has also improved a lot. Most manufacturers use digital machines to make plates, and generally require printing, printing, revision, and gift boxes to pay attention to appearance. Novelty and bright, so the layout color of the packaging box is also varied, usually a style of gift box not only has 4 basic colors, but also several spot colors, such as: gold, silver.

2. Choose paper or metal materials

Generally, ordinary color boxes are basically made of 300G to 400G copper paper, gold and silver cardboard, and special paper can also be used for special requirements. The inside of the gift box is gray cardboard and the outside is decorated with colored paper or special paper. Color paper is made of double copper and dumb copper paper. Some of them use 80G, 105G, 128G, 157G. These gram-weight papers are more commonly used. The outer mounting colored paper of gift boxes rarely uses more than 200G; because the colored paper is too thick to mount on the gift box, it is easy to foam and the appearance looks very good. rigid. Of course, this also depends on what the product is. Design the outer packaging according to the product, and then choose the paper quality and craftsmanship.

3. Printing process

Most of the gift boxes are made of printed paper, and the gift box is an outer packaging box, which pays attention to the printing process. The most taboo color difference, ink dots, and rotten boards will affect the aesthetics.

① Laminating: Laminating a layer of transparent plastic film on paper products is called laminating. Laminating film is divided into "light film" and "dumb film". The surface effect of the light film is crystal clear and bright, changing and colorful, and not changing color for a long time. With soft hand feeling and colorful surface design, it is a safe and environmentally friendly building material that can be selected according to the changes in color perception of the times. The color of the matte film can be seen to be a foggy surface, and the matte matte surface is matte after coating.

②Foil stamping: Hot stamping is to heat the metal printing plate, apply foil, and emboss golden characters or patterns on the printed matter.

③Silver hot stamping: The process principle is basically the same as that of hot stamping, except that the materials used for the two are somewhat different. In appearance: one has a golden luster and the other has a silver luster.

④UV: UV refers to UV coating, that is, Ultraviolet coating (ULTRAVIOLET), which uses ultraviolet radiation to trigger an instant photochemical reaction of UV coating, forming a bright coating with a network-like chemical structure on the surface of the printed matter.

⑤Pressing concave and convex: It is a printing method that does not use ink. It is to place the packaging box in a set of intaglio and relief plates corresponding to the pictures and texts. Under a certain pressure, the two templates are pressed against each other to make the packaging box present a relief-like concave-convex image The process of text and pattern.

4. Surface treatment of the packaging box

The surface colored paper of the gift box of the packaging box should be surface treated, the common ones are over-varnish, over-matte, over-UV, over-varnish, over-matte, hot stamping and so on.

5. Cut

Cutting is a very important link in the printing process. The cutting must be accurate to not affect the follow-up work. The key is to make a die. Die die is also important, because if die die is not accurate to your design files, it will also greatly affect the finished product. Therefore, it is generally best to take the printed product to the die master to make alignment when making die die.

6. Assemble the finished product

Unfold the cut colored paper box, and then use environmentally friendly glue to glue the finished product with a high-speed box gluer.

7. Pack and ship

Products can be packed in 3-layer or 5-layer corrugated boxes, transported over long distances and then wrapped with a woven tape to prevent damage to the carton during transportation and thus damage to the product.

Delivery: It can be delivered directly in the same city by truck, and all kinds of logistics can be delivered over long distances.

.jpg)

Latest comments