What exactly makes...

Classification and difference of metal packaging boxes

With the development of the economy and the improvement of people's living standards, a dazzling array of supermarket shelves are filled with all kinds of goods packed in metal boxes. As a professional metal packaging box manufacturer, we classify the different types of packaging boxes we produce as follows:

1. Aluminum packaging tin box

Aluminum packaging boxes are generally made of aluminum alloy plates, which are made by punching forming, surface anodizing and other processes. The design continues our factory's consistent simple style, simple and generous, and strong in practicality, which can quickly upgrade the product grade and help the product increase the added value.

The unique color, light weight and low price of aluminum material itself are generally not available in other metals. The surface treatment process of aluminum material is very diverse, and various colors can be customized according to the needs of different customers. The logo of the corporate brand value that customers need to reflect can also be expressed by a variety of production processes. In addition, aluminum is much lighter than iron or steel, and has a much higher strength and hardness than paper packaging. It can protect the product well without increasing the cost of packaging and transportation. Therefore, aluminum boxes are the best choice for packaging various cosmetics, tea, health products and electronic products.

The surface of the aluminum packaging box can be produced with various surface colors and effects through anodizing, sandblasting, hydrogen peroxide, waxing, wire drawing, atomization, etc. according to customer needs. It can also be screen printed, pad printed, inkjet, laser Laser engraving, batching, embossing, embossing, labeling, epoxy glue, diamond setting, etc. are used to make various signs required by customers.

2. Stainless steel packaging tin box

The stainless steel packaging box is made of stainless steel (#201, #202, #304) or stainless iron (#430) plates through cutting, stamping, polishing, electroplating and other processes. The anti-oxidation and corrosion resistance of stainless steel is difficult to achieve by other metals. Stainless steel can also be used through various surface techniques to enhance the surface metal texture and the finished product itself.

Stainless steel boxes used to be expensive because of their high prices. Some high-end brands such as high-end pens, high-end watches, high-end jewellery, etc. have been tailor-made to improve the brand's own grade. After many years of experience in our factory and the improvement of production technology, the original expensive production The cost has been greatly reduced, and the price has begun to move closer to the mid-end gift box market. In order to improve their brand image, many domestic brand gifts have begun to use stainless steel boxes to package their products, and many gift promotion activities use stainless steel boxes, although the cost is higher than ordinary iron The box should be high, but the added value and brand image enhancement it brings is immeasurable.

This product can be polished into a metallic glossy mirror effect. In order to meet the needs of different customers for the grade and color of stainless steel boxes, our factory has developed surface drawing and atomization effects without fingerprints, champagne gold, titanium gold, black Titanium gold, rose gold, brown gold, black brown gold, rose red and other surface crafts and colors.

According to customer needs, there are a large number of blank parts on the surface of the product. Various LOGO signs can be made by laser laser, silk screen, pad printing, transfer, drilling, glue, embossing, embossing, etc., to the greatest extent. Various requirements of customers for their own brand promotion.

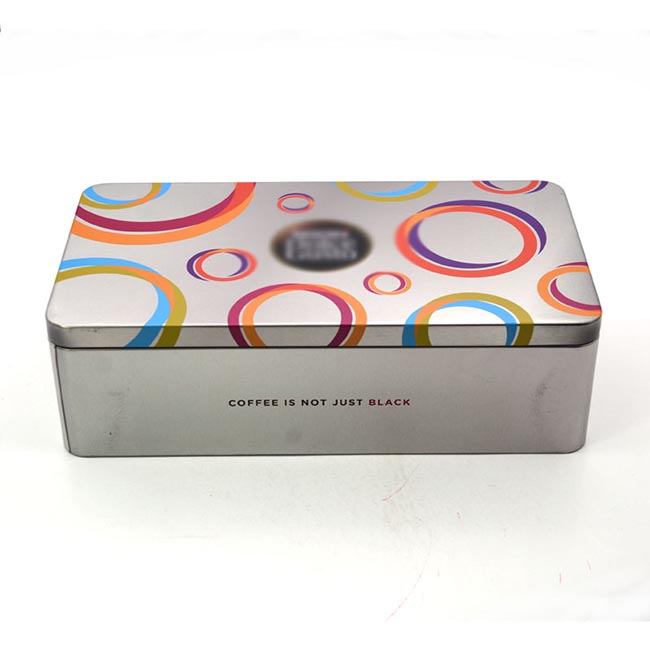

3. Tinplate packaging tin box

Metal boxes made of tinplate (tin plated iron) are made through printing, cutting, and stamping processes. The tinplate box is the earliest industrialized metal box. After hundreds of years of process improvement and development, its low price and stable physical and chemical properties make it occupy 65% of the European and American metal packaging box market.

With its excellent printing performance and metal texture retention performance, tinplate boxes have many functions in various industries. Shenzhen Shangzhimei Packaging Creative Co., Ltd. specializes in the production of tinplate boxes, with 12 years of tinplate box customization experience, and can be customized with drawings. Let me briefly describe the salient features of tinplate boxes.

1. The tinplate box is environmentally friendly packaging with good disposal performance;

2. The tinplate box has high strength and is not easily deformed during a series of processes such as loading and unloading, transportation and storage;

3. The tinplate box easy-opening lid and other easy-opening devices are widely used, which is not only convenient to open, but also the iron box body has a strong destructive anti-counterfeiting function;

4. The surface of the tinplate box has good decorative performance, has a beautiful metallic luster, and is matched with colorful graphic printing and advanced metal processing technology to form a good corporate brand image.

The above is the basic introduction of the metal packaging boxes produced by our factory. Welcome to the large gift dealers, trading companies and wholesalers to discuss cooperation matters. We will adhere to the principles of quality first, reputation first, mutual benefit and win-win to help customers solve products Actually make various problems.

Latest comments