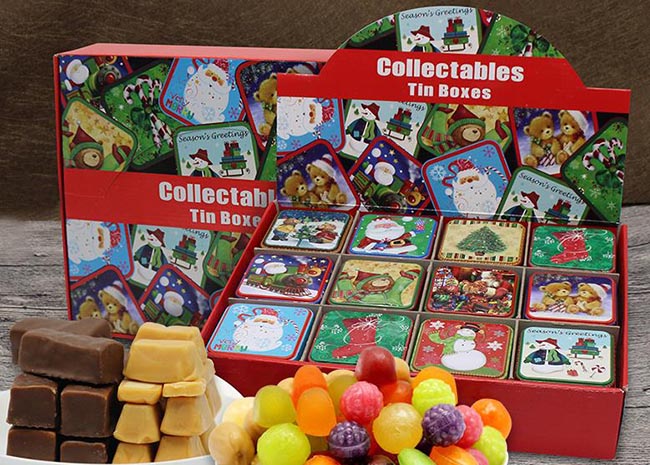

Custom decorative tin...

Tin can factory analyzes the production process of printed food tin cans

Tin can factory analyzes the production process of printed food tin cans

1. Overview of the development of food tin cans: electric soldering tins→resistance soldering tins→composite materials, widely used in the candy, chocolate, beer, and beverage industries.

2 Performance and requirements of tin can containers

In order to enable food to be stored in tin cans for a longer period of time, and to maintain a certain color, fragrance, taste and original nutritional value, while adapting to industrial production, tin cans must meet the following requirements:

1) The raw material itself is safe

2) Tin cans do not react chemically with food.

3) Meet food sealing requirements

4) Beautiful appearance and easy to carry and open

5) The production cost is economical.

Food tin cans are non-toxic to human body

Tin can food contains sugar, protein, fat, organic acid, and may also contain salt and other ingredients. The material of the tin can container is in direct contact with the food and requires a long period of storage. They should not react chemically with each other and do not harm the human body. Healthy, does not bring pollution to food and affect the flavor of food.

Food tin cans have good sealing performance

Food spoilage is often the result of microbial activity and reproduction in nature, which promotes the decomposition of food. Food tin cans are processed, sealed, and sterilized food materials that can be stored for a long time. If the sealing performance of the tin can container is poor, the sterilized food will be contaminated by microorganisms and deteriorate again. Therefore, the tin can container must have very good sealing properties to isolate the contents from the outside world, prevent contamination by external microorganisms, and prevent deterioration, so as to ensure long-term storage of food.

Food tin cans have good corrosion resistance

As canned food contains organic substances such as organic acids and proteins, as well as certain inorganic salts necessary for the human body, the containers will corrode. Some substances will produce some chemical changes inside the tin can to release corrosive substances, and the content of the food in the long-term storage process will also change slowly when contacting the tin can container, causing the tin can container to corrode. Therefore, an anticorrosive coating is plated inside the food tin container.

Food tin cans are suitable for mass industrial production

With the continuous development of the canning industry, the demand for tin can containers is increasing day by day. Therefore, tin can containers are required to adapt to factory mechanization and automated production, have stable quality, and be able to withstand various mechanical processing during the production process, with abundant material resources and low cost.

Types and characteristics of food cans

According to the nature of food container materials, the food containers commonly used in production can be roughly divided into two categories: metal cans and non-metal cans. Among the metal cans, tin-plated cans are currently the most used, in addition to aluminum cans and chrome-plated iron cans. Non-metallic cans: glass cans, plastic cans, paper composite cans.

Food tin can production process

The production methods of tin cans are: two-piece cans and three-piece cans.

1) What is a two-piece can: a two-piece can is an iron can (cover and bottom) formed by stamping only two pieces of iron. The body and bottom of the can are stamped from a piece of iron, without seams, which is also called a stretched can. There are three processes for the lid: opening-flashing-coiling, and the bottom has four steps, opening-flashing-pre-coiling line-coiling. Two-piece tin cans come in many shapes, round, square, rectangular, special-shaped, etc.

2) What is a three-piece can: a three-piece can is an iron can made of three pieces of iron (with a lid, body and bottom). The body and bottom of the can are joined by two pieces of iron, so there are more processes for the three-piece can One point, the lid: open material-flashing-coiled line can body: open material-pre-bending-cut corners-forming-buckle bone-punch (buckle bottom)-back cover. The bottom process is: cutting. The three-piece cans can be divided into many different crafts, such as back-covered, buckled-bottom, and hinged ones.

Can be divided into: round cans. Square cans, oval cans, trapezoidal cans, horseshoe-shaped cans-shaped cans.

Material characteristics of food tin cans

Food tin cans are made of tin-plated thin steel plates. Tin is plated on thin steel plates. The tin layer on its surface can maintain a very beautiful metallic luster for a long time. Tin can protect the steel base from corrosion. Function, even if a small amount of tin is dissolved and mixed into the food, it will hardly have a toxic effect on the human body. Tin is slightly bluish silver-white, has good ductility at room temperature, does not change color in the atmosphere, but forms a tin oxide film, and its chemical properties are relatively stable.

Structural characteristics of tin cans raw material tin plate

The tin plate has five-layer structure: 1. Steel base; 2. Alloy layer; 3. Tin layer; 4. Oxide film; 5. Oil film.

The production process of tin can raw material tin plate

Electroplating tin plate—→electric element iron—→ plain iron can. Hot-dip tinned plate—→hot-dip iron (eliminated).

Specification and size of tin plate of tin can raw material

The common tin plate thickness in the market: 0.2mm-0.3 mm; 0.20mm 0.23 mm 0.25 mm 0.28 mm; currently many American steel mills have changed, most of the tin plate length and width are more than 700mm, but less than 1m .For example, the length and width of tinplate produced by American Iron and Steel Company: 835×763, and the length and width of tinplate produced by ArcelorMittal Cleveland Company: 793×763.

the amount of tin plating of tin cans

Specification: 5.6g/m211.2g/m216.8g/m222.4g/m2/double-sided. Pounds/basic box means 0.25, 50, 75, 1.00; the amount of tin plating is labeled 25#, 50#, 75#, 100#. If two tin plating quantities are indicated, it is the difference in thickness of iron, which reduces the cost, and the value is the tin plating quantity on one side.

A The higher the amount of tin plating, the more corrosion resistant (emphasis). Comprehensive consideration, generally choose the middle specification and then paint.

B Note (Key points): ①Canned fruit in syrup, ②Canned fruit juice (cherry grapes, strawberry bayberry are not included/anthocyanins), ③Some canned vegetables (not included in pickles, tomato sauce/high acid), can be used The tin ion reduction effect improves the color. Therefore, the can body and the bottom of the can use high tin plating amount, that is, 22.4g/m2/double-sided, so there is no need for coating.

the tempering degree of food tin cans

Quenching and tempering degree-mechanical performance index, can be roughly understood as tinned iron hardness, the higher the harder. Empty tin cans are generally T-3.

Indexes of food corrosion resistance (the key point in actual production)

Acid leaching time lag value, iron dissolution value, tin grain size, alloy tin galvanic value. Mainly for the corrosion resistance of acidic foods, it is measured in a simulated test in an acid solution.

the pitting and dew point of food tin cans (the key point in actual production)

Refers to the surface quality of the tin-plated plate, which requires bright, smooth and no traces. Pock and dew spots are caused by uneven tin plating. In addition: aluminum alloy sheet-can, chrome-plated steel sheet.

Food tin can container coating (ink)

The most commonly used packaging material for cans made of coated iron is tin-plated sheet, but tin-plated sheet still has shortcomings. For example, sulphur-containing protein foods such as fish, shellfish, meat, etc. will produce sulfide during heat sterilization. Sulfide spots or iron sulfide are often produced on the wall, contaminating food. Colored fruits will fade under the action of the divalent stannous ion in the jar. Hydrogen swelling and perforation often occur after high-acid food cans. Some foods also have a metallic taste. This requires coating a layer of paint on the inner wall of the can to avoid direct contact between the metal surface and the food. The tinplate is separated to achieve the purpose of ensuring food quality and extending the shelf life of cans.

1) Purpose and requirements of inner wall paint for food tin cans

Cover the inner wall of the can with a protective film to separate the food from the tin layer on the can wall to prevent the metal container from contacting and corroding. Since tin is more expensive, the amount of tin plating is generally not high, and coating assistance is needed.

Purpose: To prevent food from spoiling due to chemical reactions. What happens if there is no interior paint?

. Animal foods are rich in protein (sulfur-containing amino acids). During the high-temperature sterilization process, the protein will decompose and release free sulfur. In severe cases, dark brown tin sulfide and black iron sulfide (sulfide spots) will be produced, which will damage the container and contaminate food.

. For highly acidic foods, tin iron is more active, dissolving tin iron and releasing hydrogen gas, causing container damage and food contamination. Such as tomato sauce, pickles.

. Anthocyanins canned fruits, cherries, grapes, strawberries, and bayberry. Anthocyanins are the acceptors of tin and hydrogen, which accelerate the corrosion mentioned above and the fruit will fade. Therefore, paint should be used. What about other canned fruits and vegetables?

Note: ①Canned fruits in syrup, ②Canned juice (cherry grapes, strawberry bayberry are not included/anthocyanins), ③Some canned vegetables (not included in pickles, tomato sauce/high acid), can use the reduction effect of stannous ion To improve the color, therefore, the can body and the bottom of the can use high tin plating amount, that is, 22.4g/m2/double-sided, without coating.

Since food is in direct contact with paint tin cans, the requirements for can coatings are relatively high. First of all, the coating film is required to be non-toxic to humans after contact with food; odorless and tasteless; it will not cause food to produce peculiar smell or discolor (food safety). Secondly, it is required that the coating film structure must be dense, basically free of porosity, and have good corrosion resistance (function). In addition, it is required to be able to adhere well to the surface of the tin plate, and have certain mechanical processing properties such as elasticity. It can withstand strong impacts, folding, bending, etc. during the can making process without being damaged or falling off. It can be soldered and sterilized. Withstand high temperature without scorching, discoloration or peeling off the film

Dissolution of harmful substances; the coating is required to be easy to use, to be uniformly coated, and to dry quickly (processing characteristics). Painted iron film often has a certain color, so that it is different from the tin-plated surface and will not be confused. The price is cheap and the source is convenient.

2) Composition of paint on the inner wall of food tin cans

Paint is a kind of organic compound. The raw materials of paint are as follows: oil, resin, pigment, plasticizer, thinner and other auxiliary materials. Oils and resins are the main film-forming substances of coatings and the basis of coatings. Pigments and plasticizers are secondary film-forming substances. There are many types of oils. Commonly used in the coating industry are linseed oil, tung oil, cottonseed oil and castor oil. Resin is an important part of the coating composition. It is a complex polymer compound, which can be in a solid state or a high-viscosity colloidal state. Coat the resin solution on the surface of the object. After the solvent evaporates, the resin can be cured into a film.

Grease-based coatings can improve the hardness and chemical resistance of the coating film. Generally, the paint in the tank mostly uses resin as the main component. There are many types of resins, which can be roughly divided into two categories: natural resins and synthetic resins according to their sources. Synthetic resins are also called artificial resins, such as epoxy resins, phenolic resins, and polyethylene resins. Before the successful development of synthetic resins, natural resins were widely used in the coating industry, but their quality was unstable, restricted by regions and inconvenient to use. After using synthetic resin, not only the output is increased, but the quality is also easy to control. Synthetic resin is widely used in many countries in the world

Materials, including can coatings. Most pigments are powdery solids that are insoluble in water and oil. Some of their sources are natural minerals, and many are synthetic organic or inorganic compounds. Empty can coatings rarely use pigments, but a small amount of zinc oxide can be added to anti-sulfur coatings. Solvent is also one of the components of paint, it can dissolve and dilute resin and paint, change its viscosity for coating. Solvent is a volatile liquid, which evaporates completely during the drying process of the coating, and should not leave non-volatile residues in the coating film. Although there is no solvent in the coating film, the solvent is closely related to the formation and quality of the coating film. If the solvent is used improperly, the quality will be greatly affected. Whether the solvent can be selected correctly in the production of coating iron is very important. It is best to consider the specific processing conditions and workshop equipment according to the types of different coatings. Ensure the quality of food tin cans.

3) Types and use of paint on the inner wall of food tin cans

Various coatings have their own characteristics and applicability. Different types of food have different requirements for coating and coating iron. According to the scope of application, there are anti-sulfur coatings, anti-acid coatings, anti-stick coatings, cupping coatings and external printing iron coatings.

4) Principles of commonly used paint, color and selection:

. The commonly used acid-resistant paint is 214 epoxy phenolic resin paint, which is mainly used for acid cans. 214 golden yellow.

. The most commonly used anti-sulfur coating is 214 epoxy phenolic resin coating, which is mainly used for animal cans. 214 golden yellow. That is, 214 is anti-acid and anti-sulfur dual-use paint. Has resistance to hydrogen sulfide permeation.

. Cupping paint is used for cupping, aquatic products, golden yellow

. The peeling (anti-sticking) coating solves the problem of sticky canned meat products such as luncheon meat. Pale white.

When you see the color of the inner wall of the empty can in the tin can factory, you know what product to pack.

5) Repair coating for the joints of food tin cans (the key point in production) The joint coatings are damaged by welding, so they must be repaired. Most golden yellow. Failure of the paint will cause corrosion and cause trade disputes in containers.

6) Other special paints such as mushroom 510 paint.

Each of the above items can have an impact on the quality of food tin cans. You must pay attention to it when cooperating with tin can factories. You should produce according to samples, operate according to regulations, and supervise each other to produce good quality. The above is the explanation of the printing process by the tin can factory. For more consultation on food tin can packaging, please call our consultation hotline: 086 -0755-85225331. We will provide you with a complete set of food tin can packaging solutions! Of course, if you have other questions about custom food tin cans, such as price issues, please contact us.

.jpg)

Latest comments