Anlässlich von...

How to Make Creative Tin Packaging Metal Boxes

Metal packaging is one of the safest solutions for preserving food and cosmetics. Because it is recyclable and environmentally friendly, it is cheaper and more economical than other packaging materials. Here are the main points to keep in mind when designing metal packaging.

1. Materials selected for metal box

Materials used in metal packaging are important because they must resist rust and corrosion. Aluminum and tinplate meet this standard and are lightweight, strong and durable, among other good build qualities.

Both metals reliably protect food from environmental factors such as bacteria, moisture and light. Aluminum is especially useful because of its strength as a barrier. Aluminum comes in all forms from cans to boxes to protect food. A sealing strip is added to the bottle cap to make it airtight, which can further extend the shelf life of the food. Consumers love metal packaging containers because they are associated with strength and durability. More and more consumers are also aware of the sustainability of aluminium, giving it a modern and clean image. Global metal packaging is growing rapidly and the market will reach $141 billion by 2022, according to market research firms.

At the same time, the world market for micro-packaging is also rapidly increasing, providing security made of various materials, including metals. Micropackaging comes in the form of bags, pouches, trays, cartons, etc. The more nanomaterials are used for packaging, the greater the need for micropackaging. The demand for tinplate also continues to increase. Some of the advantages of tinplate packaging are the softness of the solderability in many shapes. The history of metal cans in food marketing dates back to the early 19th century. Its applications have grown from packaged wines to a wide variety of food as its future seems to continue.

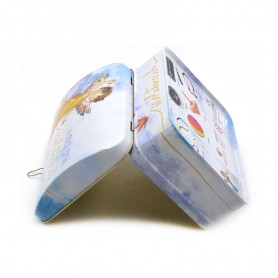

2. Shape of metal box

Packages come in a variety of shapes from round to square and rectangular. Special shapes such as cones and octagons allow for modern packaging, relying heavily on consumer research and designer imagination. Numerous studies have shown that shape plays an important role on a consumer subconscious level. Everyone has a unique relationship between shape and shape, which also helps define the consumer's impression of a product. According to a study published by the market research agency in the first half of 2019, consumers responded well to the angle and alignment of shapes and were more satisfied with the orientation and shape of circles. The study further found that the shape of the water droplets can provide positive opportunities for designers.

3. The tightness of the metal box

The package must be closed and sealed. For example, guards, screws, hinges, compact dimensions and special guards. Hinges exist as common solutions for preserving lids, lids, lids or pegs and boxes. Some popular sealing caps for food packaging include press twist, screw caps and standard continuous thread caps. Aluminum enclosures are often used as walls against dust, oxygen and moisture. Aluminum helps to reseal the container and reuse it through hinges and other connectors. It is a material that can be used in any shape, so it can easily be the basis for innovative closed styles. Other accessories include threads, lugs, locks and adhesives.

4. Printing effect of metal box

Designers can add effects to the pack, such as drawing attention by pressing letters to create a 3D effect. A greener effect can be achieved by using smaller containers and lighter or fewer materials (with an emphasis on recyclables). The messaging role of the manufacturer is to share as much product information as possible and get in touch with consumers who they consider to be profound researchers. Regarding effects, the main concept that should be remembered is to convey the theme and emotion of the product to the consumer, and the effect will not confuse the consumer. When replacing metal packaging, designers must keep in mind the consumer’s existing familiarity with the brand. Any attempt to create a closer connection with consumers through packaging should consider the consumer history of the product in order to remain familiar in the store.

One of the disadvantages of metal packaging is that consumers often do not see the metal, which requires innovative design windows. Metal cans are usually coated with an organic protective layer for safety and cleaning.

5. Color matching of metal boxes

No matter which product is used, color can provide longevity and differentiation. Packaging designers have been learning how color plays an important role in attracting consumers to purchase packaging. As with other packaging components, each has their own personal color associated with mood. Bright colors tend to be associated with happiness and excitement, while muted greens and blues are associated with earthy images and relaxation. Color psychology has now become an essential part of marketing and branding. Various scientific studies have shown that color is a factor in consumers' purchases. Therefore, packaging designers must use target market research to use appropriate colors for packaging. Some marketers believe that color is the most important trigger for consumer decision-making.

Latest comments