Custom metal tin...

Things you must pay attention to when customizing tin boxes

Nowadays, many food manufacturers have their own unique ideas and LOGO, and more and more food manufacturers have begun to find tin box manufacturers to customize packaging boxes suitable for their products. However, many merchants have limited knowledge of tin boxes before, so they basically cannot express their requirements for packaging. This article will teach you some knowledge points you need to know about custom tin box packaging.

1. The design, style and specifications of the iron box

Here we talk about the design of the tin box, mainly through communication with the customer, to obtain the customer’s demand, let the customer provide the pattern made by the tin box packaging design or the pattern provided by the customer, logo brand printing, etc., boutique packaging, high-end, two-dimensional Code printing, etc., and whether you need spot color or four-color printing, you must communicate clearly with customers. In addition, you also need to ask customers what styles they need. Various styles of tin boxes can be customized according to customer needs: such as rectangles, squares, circles, special shapes, etc. Another specification is the size of the product. Generally, a tin box manufacturer will have a mold when producing a tin box. Normally, a larger company will have several thousand sets of general molds.

2. tin box accessories, materials and craftsmanship

Here we continue to explain that when iron boxes are generally made, they will be packaged for them by the manufacturer of the iron boxes. Generally, buyers will ask their partners to order suitable outer packaging, such as hand-held or outer packaging, here. Everyone’s accessories are introduced: magnets, ribbons, EVA foam, plastic trays, sponges, PVC/PET/PP windows, these are topics frequently asked by customers. Here we Shangzhimei can also solve problems for customers, if you need to customize, you can contact us. Furthermore: Talking about the material of the iron box, the issue of the material of the iron box is more abstract. I also introduced it to you earlier, and today I will tell you about it: the main material of the iron box is tinplate, which is also called tinplate because It is not easy to rust and has a wide range of uses. Tinplate is an iron sheet with a layer of tin plated on the surface, it is not easy to rust, also called tin plated iron. Here we talk about the process: the process of the general tin box: it is a packaging box made of tinplate through different processes such as welding or stamping and buckle. For example, iron boxes are different in: (printing, laminating, bronzing, UV, glazing, bumps, etc.).

It must be emphasized that tin plated iron is required, not base plate iron. In order to fight price wars, many manufacturers blindly ask for prices and lower quality requirements. They use base plate iron to pretend to be tin plated tinplate. Anti-corrosion, and the substrate iron is not processed by this layer of process, directly on the machine to print, the cost is reduced, but corrosion will appear in a short time, so customers must be vigilant.

3. Determine the material, the customer needs to understand the thickness of the material, how many wires are used to express the thickness of tinplate, the unit of wire here is actually millimeters, such as the thickness of 0.1 mm, usually 10 wires, which can be measured with a micrometer caliper. The thicker the material, the stronger the iron box.Of course, the thickness of the material must be determined according to the size of the box to avoid unnecessary excess quality.

4. The material is determined, just wait for the communication of the printing process. This printing process depends on your requirements for the visual effect that the pattern needs to show. The ordinary and conventional are four-color printing and spot color printing. Of course, the more spot colors you use , The printing cost is relatively higher, and there will be matte, bright, partial bright and partial extinction and other appearance performance techniques, which can also affect the cost of packaging; for appearance printing performance requirements, there will be explosive oil , Rubber oil, etc., these are more advanced printing processes, of course, the cost is also higher

5. The color, type and transportation of the tin box

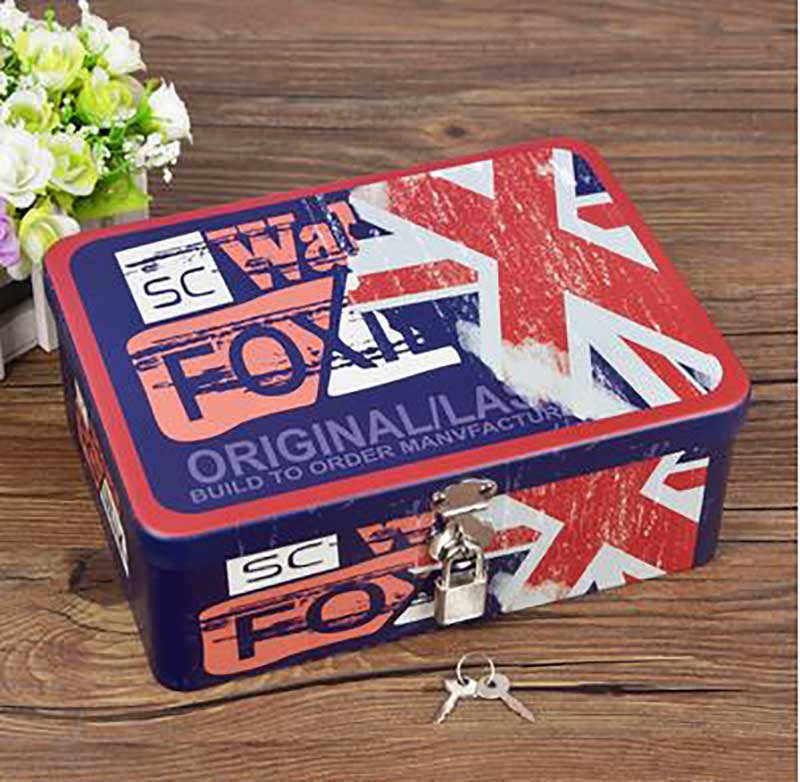

Finally, we all understand that when the tin box is made, we will pay special attention to the selection, such as the color of the tin box: the custom colors of the tin box are (red, white, black, colored, yellow, black and white, orange, purple, gold, Silver, gray). The type of tin box (skin care products, cosmetics, tea, food, specialty products, electronic products, food, health care products, moon cakes, medicines, red wine, white wine, holiday gifts, etc.). Iron box transportation method (air, sea, truck, train transportation).

In short, to customize a tin box that meets your heart's desire, you must seek a reliable and reliable factory that speaks credit for cooperation and communication~~

Latest comments