سواء كنت من عشاق...

Introduction to the artist's watercolor metal box and its production process

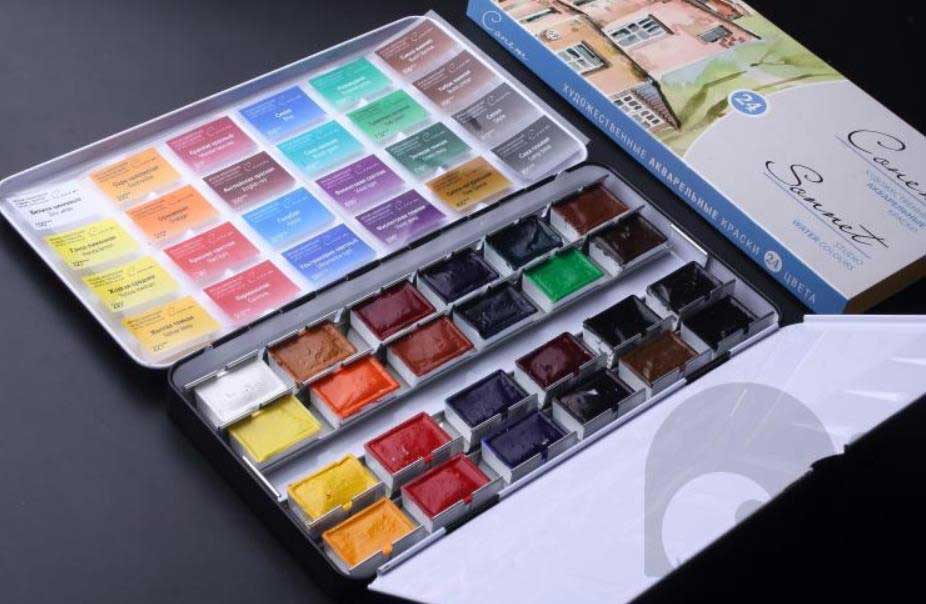

24 watercolor metal box (L3" x W5" x H3/4")

Material: Tinplate

Color: black, red

Origin: Made in China

Application: DIY crafts

Weight: 100 grams

This custom watercolor metal box is coated with black or pink enamel on the outside and white on the inside. The interior is divided into 12 grids, each box has a mixed surface, a lid and a folding palette. It is made of first-class food-grade tinplate, and its thickness is 0.23mm-0.35mm; there is a thumb ring on the base of the watercolor metal box, which can hold the box in the hand when sketching. The box is equipped with a guide rail for the tube or a movable entrance with a guide rail for the half-tray or the entire tray. Each box can hold 12 half or 6 full colors.

6 artists watercolor metal box

Color box-light-weight sketch box, equipped with 24 artists professional watercolor semi-guide wheels.

Lightweight and durable. Black enamel metal box with integrated paddle and mixing zone.

Very suitable for outdoor work or study.

Including the colors of the artist's professional range:

-Windsor Yellow, Indian Red, Natural Color, Tan, Penn Grey, Ivory Black, Chinese White, Aureolin, Indian Yellow, Windsor Red, Permanent Alizarin Carmine, Permanent Pink, Windsor Dioxin Purple, French Ultramarine, Cobalt blue, Windsor blue, sky blue, dark ocher, natural ocher, lemon yellow, Windsor orange, Prussian blue, emerald green and indigo.

The watercolor metal box is manufactured according to the classic European method. Different from the current general watercolor paint box-the characteristics of the watercolor metal box are corrosion resistance, high strength, very good ductility, and non-toxic, so people like to use it to make watercolor boxes. However, to ensure the quality of these watercolor metal boxes, first of all, every step of the process of making watercolor metal boxes must be paid attention to because each step will affect the quality of the product. Only in accordance with the rules and regulations can we guarantee the production of qualified products. The exquisitely designed watercolor metal box perfectly meets your needs for easy coloring. Suitable for home or studio painting, outdoor or travel painting. The watercolor metal box is of suitable size and is convenient for the painter to carry. Made of high-quality tinplate material, it is strong, reusable and light in weight.

The making process of custom watercolor metal box

Each artist's watercolor metal box is completed step by step by iron material-printing-cutting-stamping-assembly-packaging.

1. The raw material of the watercolor metal box-iron plate

Iron material: Generally, after confirming the order, the most suitable iron material will be ordered according to the close layout drawing, iron material thickness and size. Regarding the identification of iron material quality, you can usually visually check whether there are scratch marks on the surface. Whether the lines are uniform, whether there are rust spots, etc., the thickness can be measured with a micrometer, and the hardness can be felt by hand.

2. Printing process of watercolor metal box

Printing: After the layout diagram is given to the printing plant, the printing plant arranges imposition printing, and usually provides a template for the printing plant to follow the color. During the printing process, you should pay attention to whether the printing and color matching follow the template, whether the set position is accurate, and whether there is Stain, whether there are scars, etc. The printing houses generally responsible for these problems can control themselves.

3. Cutting process of iron material

Cutting: After the printed iron material is returned to the factory, it can be cut and cut according to the cutting table. Before the cutting table, pay attention to whether the operator cuts according to the knife edge line and whether the length is consistent and uniform. Whether workers scratch each other when unloading, etc., the quality must be checked at the initial operating station.

4. Stamping process of watercolor metal box

Stamping: It is to press the iron sheet into shape on the punching machine. This is the most important work for making watercolor metal boxes. Usually, a metal box needs to be divided into many processes to complete. The general process of the two-piece metal box with hinged lid is: lid: opening-flashing-winding. Bottom cover: cutting-flashing-pre-coiled line-coiled line.

In the watercolor metal box stamping process, the material loss is usually the largest. In the production process, pay attention to whether the work operation is standardized, whether the surface is scratched, whether there are batch seams in the coil, and whether the button bone is fastened. The usual practice is Arrange to confirm the production of large samples before the production of large goods, and produce according to the confirmed large samples, which can reduce a lot of trouble.

5. Packaging of the finished watercolor metal box

Packaging: After the production is completed, the packaging department is responsible for cleaning and assembling, putting in plastic bags and packing. This link is the finishing touch of the product. The cleanliness of the product is very important. Therefore, it is necessary to do a good job of cleaning before packaging, and then package according to the packaging method. For products with many styles, the style number and box edge must be aligned and placed. put. In the packaging process, attention should be paid to minimize the influx of defective products into the finished product, and the packing quantity must be accurate.

Latest comments